Original Source: https://www.articleblock.com/assemble-secrets-for-the-modern-printed-circuit-board/

Making a printed circuit board (PCB) is a complicated process because a lot of electrical components need to be adjusted in a precise manner to make the board functional. The circuit structure essentially decides how one should assemble the PCB and this will depend mostly on the gadget where the PCB would be ultimately used. In this short article, you will learn more about the different levels involved in assembling a modern printed circuit board.

What are the levels of PCB assembling?

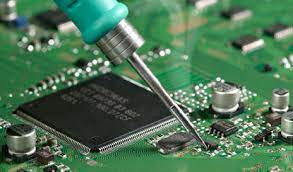

Soldering electrical components is the most essential aspect of assembling the PCB, otherwise, all you will have is just an empty board without any use. These days, HDI printed circuit boards have become more popular because of their versatile use.

You should remember always that assembling a PCB is different from making it from scratch. A lot of complicated levels are present during the manufacturing process, including the designing of the board to locating the appropriate materials. The electronic components also have to be soldered and attached to the PCB to make it functional. Only then, will the board be suitable for use in any electrical gadget. OF course, the method of assembling the board will depend largely on the types of electrical components that are to be used and the design of the circuit board in general.

Two main procedures of construction are followed for making the PCB operational: through-hole and surface mount construction. The only difference in these two processes is the way that the electrical components are attached to the PCB. It is important to note here that both these methods would need to fix the individual component leads with the PCB via soldering through the process of PCB fabrication. Companies like PCB-Togo are quite adept at producing PCBs in this manner.

Conclusion

You would have to have a lot of precision in your abilities to assemble a printed circuit board after soldering in all the different components inside it. It will take you plenty of time to do this in a proper and thorough manner, as a result of this, we have high precision machines that can be used for the fabrication procedure. These machines will also enable the mass production of different types of PCBs. A combination of all these factors will allow us to make more electronic gadgets of different kinds in a quick period. Hopefully, the information mentioned in this article will have helped you.