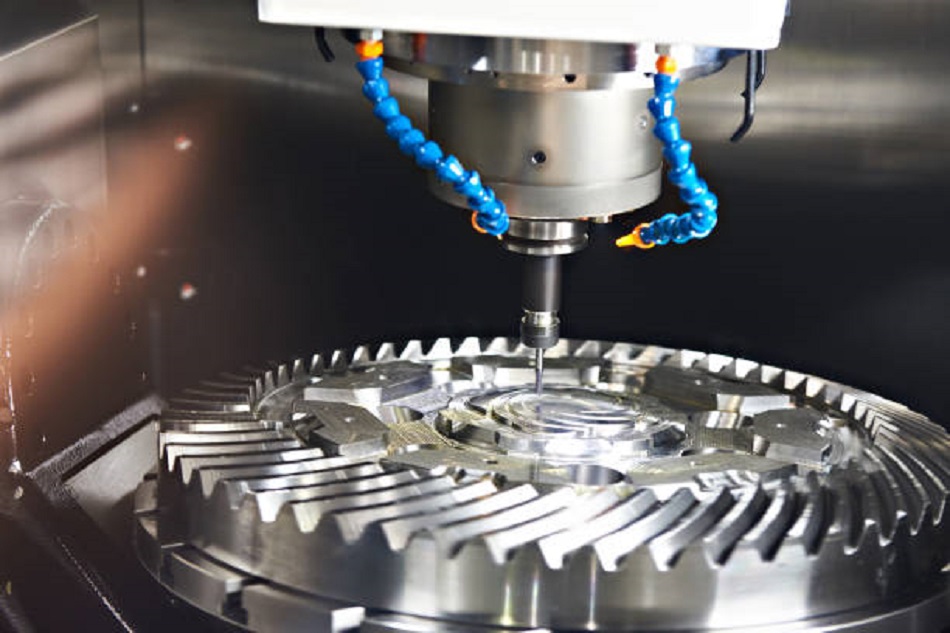

The repair and maintenance of CNC machine devices are exceptionally vital. Time ought to be taken within the work to sensibly orchestrate the machine devices’ assessment work to dodge harm to the work caused by the machine tools.

There are numerous sorts of CNC machine instruments, and different sorts of CNC machine apparatuses have diverse characteristics due to their varied capacities, structures, and frameworks.

Particularly, concurring to the sort, show, and genuine utilize of the machine instrument and alluding to the machine instrument manual’s prerequisites, the vital occasional and evaluated support framework ought to be defined and established.

Thus, here are some essential factors that would tell you that why Regular CNC Machine maintenance with Mitsubishi servo motor is important

Why you should Consider Maintenance for your CNC Machine?

- Every day CNC Machine Maintenance

These are the “apples a day” that keep your CNC machine apparatuses out of the machine crisis room. They sound basic, and they are. Doing a couple of minor checks after each day or each move can offer assistance to capture an issue; sometimes, recently, it snowballs into a major breakdown. The machine apparatus pros suggest that these are some of the things that you should consider:

- Check those liquids before anything. CNC machines require satisfactory liquid levels, such as lube and water-powered liquid. Working every day together with your machines will grant you an excellent standard for how quickly the liquids have to be recharged. When machines begin utilizing liquid at the following rate, have your appliances checked. Intemperate liquid can be a sign of problems.

- Give them oil after the first step. Oil is the smooth administrator that keeps all the working parts moving and cutting. Not all machine shops check oil focuses each day, but we prescribe looking at all moving parts for dry spots. A quick shot of oil goes a long way to diminishing undesirable wear. Renew with a Cloth, and suggest this to Fanuc Servo drive

- Wipe down all the surfaces to appear a slight sparkle by cleaning absent the shop grime and the other parts. Wiping the machine down day by day will keep the littler metal shavings from building up in damage-prone ranges – such as the way cover seals.

- Spring Cleaning For Processing Machines & Lathes

When performing a careful spring cleaning on your processing machines with a Mitsubishi servo motor, you need to consider this:

- Make beyond any doubt the machine tool’s walled in area is cleaned, and chips are evacuated from beneath the way covers the region. Fundamentally, perform a full-enclosure cleaning!

- Check that all oils are at ordinary levels and working correctly. Perform delicate alterations (in case fundamental) on the programmed instrument changer, so it proceeds to alter devices faultlessly with no hang-ups or jams.

- Complete a careful assessment of the shaft and axle drivetrain to guarantee there are no contaminants that would influence the spindle’s by and significant life.

- Check shaft belts for pressure, oil, chips and wear to dodge superfluous or awkward downtime and dodge compromising a portion amid cutting operations.

- It is suggested to perform a ball bar test to check the machine’s planes’ circularity and arrangement.

- Get it your hardware and its support prerequisites.

Each machine will have satisfactory working conditions with Fanuc Servo drive, manufacturing plant suggested benefit interims, and endorsed upkeep plans; this data is included within the Operation Manuals. Be beyond any doubt your administrators examined the manuals to familiarize themselves with the equipment’s ideal execution specs, what status messages cruel, and suitable security methods.