There are many syringe filters accessible on the market, and these filters come in a wide variety of materials, pore sizes, and diameters. When it comes to picking the most suitable one for your application, this might make it seem like a bit of a minefield to choose the best option. To make the selection process easier to understand, we divide it into several distinct phases.

Syringe Filters

Before conducting an analysis using a technique such as high-performance liquid chromatography (HPLC), ion chromatography, gas chromatography, inductively coupled plasma (ICP), or dissolution testing, particulate impurities can be removed from liquid and gas samples using membrane-based syringe filters, which are disposable devices. Filtration of samples correctly enhances the quality and consistency of analytical findings while also reducing the amount of time spent maintaining analytical instruments. When time is of the essence, many people turn to disposable syringe filters for their filtering needs. The selection process needs to begin with the application.

Sterile Or Non-Sterile Syringe Filters

Although a syringe filter’s main purpose is to eliminate particles from a sample of liquid, the kind of filter you choose will depend on the use it will be put to. You may choose between sterile and non-sterile syringe filters.

Filters made of sterile material are inserted into sterile syringes to sterilize non-sterile liquids or clarify sterile solutions. Find out more about the several applications of sterile filters.

Available filtering and the purification of samples may be accomplished using non-sterile syringe filters.

Find out more about the several applications for non-sterile filters.

How To Make Use Of A Filter For A Syringe

After determining which syringe filter and syringe would work best for your sample and application, you will need first to load your sample into the syringe and then connect the filter to the end of the syringe. If using a leur lock filter, check that the filter is appropriately locked in the syringe tip. “Top-up” the syringe by forcing a few drops through the filter while holding the syringe so that the filter is pointed upward.

After positioning the filter tip above the collecting container, apply some slight positive pressure to the syringe to force the sample through the filter within the syringe. Remove the filter from the syringe and then suck air into the syringe to cleanse the syringe filter and get the highest possible sample throughput. The filter should then be reattached, and while pushing the plunger, some air should be forced through the filter.

Syringe Filter Membranes And Housing

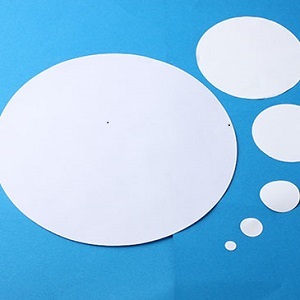

The membrane and housing of a syringe filter are the two fundamental elements that allow the device to be classified. To choose the appropriate filter, you need to ensure that the application is compatible with both of the filter’s components. Housings for syringe filters are matched to end applications according to their composition and format, whereas membranes are matched to applications according to their composition, filter diameter, and pore size.

Syringe Filters By Pore Size

When it comes to research and medical applications, the two membrane pore sizes used the most commonly are 0.45 m and 0.2/0.22 m.

In most cases, 0.45-micron membranes are employed for general filtration and particle removal applications.

For the most part, solution sterilization uses membranes with a pore size of 0.2/0.22 micrometers, also known as sterilizing-grade membranes (bacteria removal).

How Is The Pore Size Of The Membrane Determined

The bubble point test is the most straightforward way of determining the size of the pores in a membrane. The pressure at which a steady stream of bubbles may flow through a membrane that has been completely saturated is known as the bubble point. The bubble point test is a method for determining the maximum pore size of a membrane by using the inverse connection between bubble point and pore size.

The bubble point of membranes with a thickness of 0.45 m is normally between 10 and 25 psi, while the bubble point of membranes with a thickness of 0.2 m is often between 40 and 50 psi. Alternatively, bacterial retention may also describe a sterilizing-grade Membrane filter, with bacteria of known size being used in the experiment.