While the field of materials management may not be the most profitable, a safe and efficient process is impossible without it. Movement of materials is essential at every stage of any product, manufacturing or manufacturing process. The flow of raw materials, intermediates and finished products sets the absolute limit on how fast a process can run. Industrial equipment designed for this area has to do its job without fail to keep workers safe and moving up the production line.

Lifting and Rigging – Hoist Rings and more

When lifting operations involve material handling, safety and efficiency take center stage. The main safety rule for cranes and lifting equipment is to never load on other workers. In addition, all lifting industrial equipment must be designed to support twice the maximum rated load so that failure does not result in more than damage to process equipment and injury. Every component of the system, from the smallest hoist rings to the rigging, must be rigid and durable; The weakest link will break first.

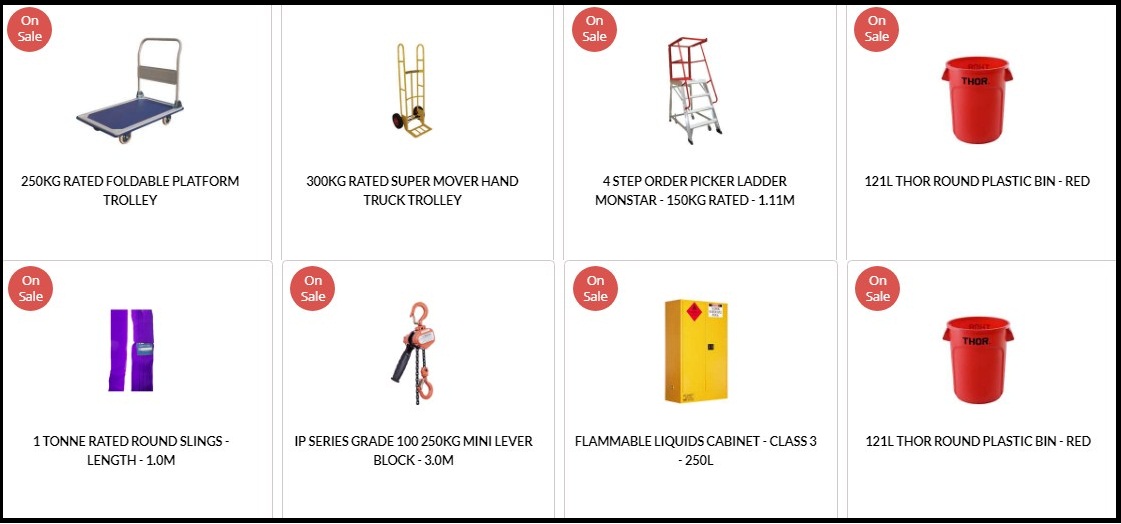

When hoist rings are considered, they can be used in a variety of configurations for flexible material handling systems. The material handling equipment at equip2go.com.au comes in different sizes, materials and with multiple swivel points. For example, fixed hoist rings are the strongest configuration available, but sacrifice manoeuvrability. A system designed to manoeuvre loads over complex paths or to load goods into process steps may not use a fixed mount hoist ring.

On the other hand, the swivel mounts offers freedom of movement for more complex aerobatics. Hoist rings can be designed with three independent swivel points for maximum flexibility in multiple directions. With additional parts, extra care and maintenance is required to keep all swivel points lubricated and moving freely.

As far as rigging goes, strength and durability are again top priorities. Select rigging rated for at least twice the required load to ensure safety as well as adequate room for wear and tear. Select materials used in any working conditions. For example, in a chemical plant containing corrosive chemicals, stainless steel will last longer than carbon steel. It is safer to use more expensive materials that do not need to be replaced as often.

Material handling process

Drum handling is a unique matter. In addition to the standard hazard, drums usually contain hazardous materials, making spills even more dangerous. While falling sheet metal can cause damage and injury, a dropped drum can inhale or release hazardous fumes, causing serious injury over a wide area.

Use the same logic when choosing lifting equipment. Always choose a crane that is designed to carry heavier loads than expected.

Castor and loaded on wheels

The easiest way to move anything is to put some wheels on it. However, using casters and wheeled carts safely involves more effort and consideration.The load requires five casters to be properly balanced and ready for transport. A rectangular load may only need four wheels, but any round or cylindrical load needs a fifth support point.

With this in mind, the first safety rule for drums is to never try to shake a drum by turning it on its side. No matter how close the drum is to where it needs to go, always use material handling equipment such as a drum dolly or cart. Drums can also be loaded onto pallets and driven through the worksite by forklift. Specially designed drum handlers are also available that combine a lifting device with a movable cart to securely combine all material handling functions for the drum into one piece of equipment. The bottom line is never trying to roll the drum.