Since the recession hit, businesses both large and small have acted like deer in headlights. They are fixed in their tracks and fail to get out of harm’s way. This is as true in the material handling equipment and management industry as it is everywhere. However, there are also some success stories. These are the business leaders who were never satisfied in boom times. What solutions have they come up with?

A good business executive always strikes a balance between optimism and caution. In bad times there are opportunities and in the best of times there are dangers. For example, while many are lamenting the current lack of demand, more forward-thinking leaders point to the fact that more than 200,000 people are born every day. These will be the future customers.

On the other hand, they do not ignore the challenges that exist at the moment. One solution they are considering is more automation, not less. This may seem counter-intuitive to many, who associate automation with costs that will only pay off in boom times. What is the logic of this?

Many material handling experts argue that the industry is already automating and that’s part of the problem. For example, robotics was popular until the recession hit, and robotics suppliers reported a major slowdown in demand in 2010. Interestingly, in the third quarter of the year, requests for new proposals increased dramatically.

The reason for this dramatic increase in interest in automated material handling equipment Perth is that businesses are realizing that if they automate key components of their systems, they can run their business more cost-effectively. A major shift in thinking has been aimed at those core components.

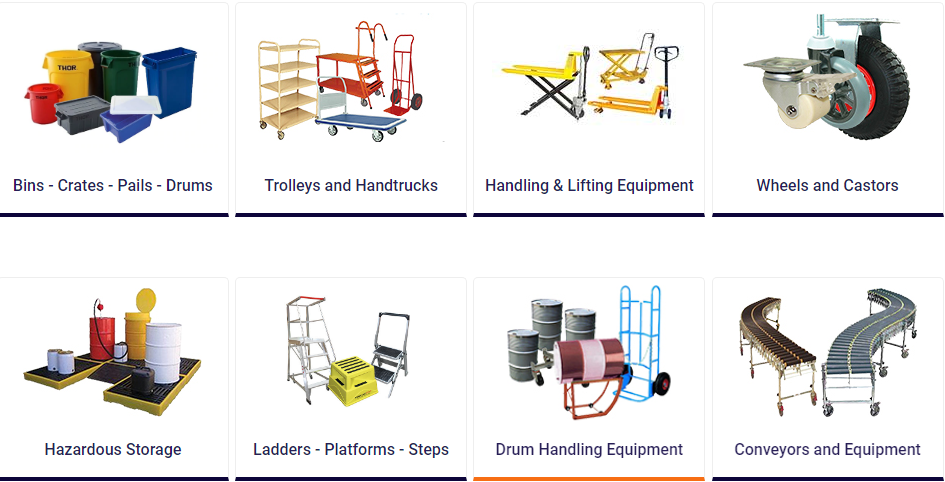

Small manufacturing plant and warehouse operators may wonder how automation suggestions can apply to them. Robotics and other high-tech solutions are astronomically expensive for small business operators. However, the principle remains the same. For example, a large shipping company can increase efficiency with robotics solutions, a small warehouse can increase efficiency by investing in a new pallet rack system.

Many older warehouses “make do” with old pallet rack systems. When his business started, he bought a basic selection of pallet racks and continues to use them because he has an efficient system. However, new pallet flow racks or stacker racks can potentially make a dramatic difference in material handling efficiency. The stuff handling solutions that come with huge multi-national corporations may not be applicable to every business, but if you look more closely, they are.