There are numerous people who show interest in purchasing rubber products because of their water resistance, strength, heat and longevity. While buying rubber products, you do a thorough research and then you select the right products that suit your requirements. There are many other industries that make rubber products such as construction, medical, automotive and manufacturing sectors. In the present era, there is a high demand for rubber. There are countless companies that source the best and reputed rubber manufacturing industries and then carry out the business to supply the desired rubber products. The survey reports state that the rubber product market will hit the market by the end of the year. There are many international companies which have a massive demand for rubber products in the footwear industries. The uses of industrial rubber products are on the rise these days. Belts, pipes, pipelines, and gears are just a few of the many uses for which natural rubber and synthetic rubber are applied in a variety of end-use industries. The fast development in tire production has been a significant contributor to the expansion of the industrial rubber goods business.

Note About Rubber Harvest and Properties

Rubber is derived from rubber trees all over the world. A rubber tree can produce rubber for approximately 25 years. Harvesting of rubber begins when the trees of rubber are five-years- old. The prime source of natural rubber is Asia. A climate with zero frost and heavy rainfall is ideal for rubber plantation. Rubber manufacturers are faced with the task of enhancing product performance while also increasing their production efficiency and lowering their total cost of ownership. Their industrial rubber products additives enable manufacturers to customize the mechanical, electrical, and thermal qualities of their goods while providing the most possible value to their consumers.

You should know that rubber material has a wide range of configurations and properties. When the natural rubber is purified, then a chemical is produced synthetically. The synthetic rubber is used extensively in many products and applications. In the present days, synthetic rubber is used everywhere. Rubber is flexible, waterproof and stretchable.

Rubber comprises long polymer chains that are connected to points. When rubber is vulcanized, then it creates disulfide bonds in the polymer chains which further shorten the sections of chains. This forms a tighter chain which makes the rubber harder and stronger.

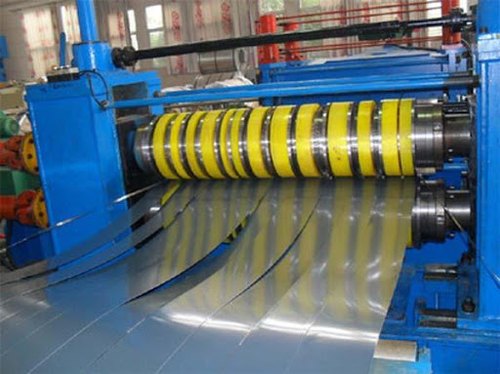

The best substitute for natural rubber is synthetic rubber. Adding sulfur and vulcanization are used to enhance the properties of natural rubber. At times, synthetic rubber is reckoned as the best choice. In the current days, the synthetic rubber is used in various industrial applications such as printing industry. Most printers such as the large-scale commercial printers use rubber covered rollers. Rubber molded products are used in household and industrial applications. The largest consumers of rubber are belts, hoses, tyres, tubes, flooring, matting and medical gloves.

There has been a high demand for rubber products. From making belts, roofs, mechanical products to hoses, there has been a steep rise in the rubber materials. The silicone rubber products are versatile and can be used in various applications. Moreover, this type of rubber is resilient and durable. Silicone rubber has become a top choice of many industries, as this type of rubber can be sold in the form of strips, molds and sheets.

Resistant to weather conditions

Industrial rubber products can be used widely in outdoor applications. The industrial rubber can withstand extreme weather conditions. Whether it is heavy wind, UV rays, or rain, the weather conditions do not have a negative impact on the rubber material. Rubber products perform in an excellent way in the outdoor environment. Owing to the flexible weather conditions, many industries are taking interest in manufacturing rubber products. Even in the hottest climatic conditions, the rubber material has no negative effect on the changing weather conditions.

There are different rubber grades which can resist high temperatures that can be low or high. Few rubber types possess the ability to withstand the temperature which ranges from -55 degree centigrade to 250 degree centigrade. The silicone rubber can withstand a low temperature that ranges from -100 degrees to as high as 310 degrees. No matter what the weather changes are, the rubber products will last for a longer period of time.