What are UPVC Valves and How Do They Work in Water Plants?

Water plants are facilities that treat and distribute clean water to households and industries. The process of treating water involves many stages, including filtration, sedimentation, disinfection, and distribution. To ensure that the water treatment process runs efficiently and safely, various equipment and devices are used, including valves. Valves are critical components that regulate the flow of water, isolate sections of the treatment process, and control the pressure and temperature of the water. UPVC valves are among the most commonly used valves in water plants due to their unique properties.

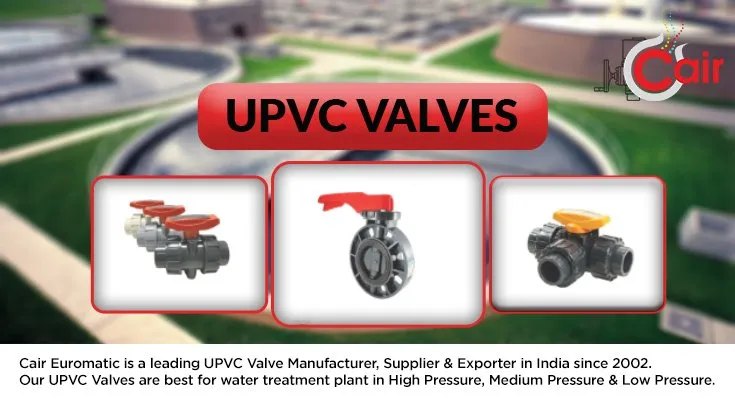

UPVC stands for Unplasticized Polyvinyl Chloride, which is a type of plastic that is rigid, durable, and corrosion-resistant. UPVC valves are made of this material and are designed to withstand harsh environments and chemicals. They are also lightweight and easy to install, making them ideal for use in water plants. UPVC valves come in different sizes, types, and shapes, depending on the specific application and function. Some of the common types of UPVC valves used in water plants include ball valves, gate valves, globe valves, check valves, and butterfly valves.

Benefits of Using UPVC Valves in Water Plants

UPVC valves offer several advantages over other types of valves when used in water plants. First, they are resistant to corrosion, which means they can withstand the harsh chemicals and environments found in water treatment facilities. Corrosion is a significant problem in water plants because it can damage the valves and compromise the water quality. UPVC valves also have a longer lifespan than other types of valves, which means they need less maintenance and replacement. This translates to cost savings for water plant operators.

Second, UPVC valves are lightweight and easy to install. Unlike heavy metal valves, which require specialized equipment, UPVC valves can be easily handled and installed using basic tools. This makes the installation process faster and more efficient, reducing downtime and labor costs.

Third, UPVC valves are versatile and can be used in various applications and functions. For example, ball valves are ideal for isolating sections of the treatment process, while check valves prevent the backflow of water. Globe valves and gate valves are used for regulating the flow of water, while butterfly valves are used for controlling the pressure and temperature of the water. UPVC valves can also be used in conjunction with other equipment and devices, such as pumps, filters, and pipes, to optimize the water treatment process.

Factors to Consider When Choosing UPVC Valves for Water Plants

Choosing the right UPVC valve for water plant requires careful consideration of several factors. One of the critical factors to consider is the size and type of the valve. The size of the valve should be compatible with the pipe or equipment it will be connected to, while the type of valve should be appropriate for the specific function and application.

Another factor to consider is the operating conditions of the water plant. The valve should be able to withstand the pressure, temperature, and chemical exposure that it will be subjected to during the water treatment process. The valve should also be compatible with the type of water being treated, such as potable water or wastewater.

The manufacturer of the UPVC valve is also an essential factor to consider. It is essential to choose a reputable manufacturer that uses high-quality materials and follows strict quality control standards. A reliable manufacturer should also provide technical support, warranty, and after-sales service to ensure the valves are working correctly and efficiently.

Maintenance and Repair of UPVC Valves in Water Plants

Proper maintenance and repair of UPVC valves are essential to ensure that they continue to function efficiently and reliably. Regular maintenance can help prevent costly repairs and replacements, and extend the lifespan of the valves. Here are some tips for maintaining and repairing UPVC valves in water plants:

Inspect the valves regularly: Regular inspections can help detect any signs of wear or damage, such as cracks, leaks, or corrosion. Inspect the valves at least once a year or more frequently if required.

Clean the valves: UPVC valves should be cleaned periodically to remove any dirt, debris, or buildup that may affect their performance. Use a soft cloth or brush and mild soap and water to clean the valves.

Lubricate the valves: Some UPVC valves may require lubrication to function correctly. Follow the manufacturer’s instructions on the type and frequency of lubrication required.

Replace worn or damaged parts: If any part of the valve is worn or damaged, such as the seals, gaskets, or O-rings, replace them immediately to prevent leaks and other issues.

Repair or replace valves as needed: If a valve is beyond repair or has reached the end of its lifespan, it may need to be replaced. Consult with a qualified technician or engineer to determine the best course of action.

In conclusion, UPVC valves are critical components in water treatment plants, regulating the flow of water, isolating sections of the process, and controlling pressure and temperature. They offer several benefits, including resistance to corrosion, longevity, ease of installation, and versatility. Choosing the right UPVC valves and maintaining them properly can help ensure the water treatment process runs efficiently, safely, and cost-effectively.