Pneumatic valves are an essential component in many industrial automation systems. They are used to control the flow of compressed air or gas to actuate different types of machinery. In this blog, we will discuss the different types of pneumatic valves, their applications, and the benefits of using them in industrial automation.

What is a Pneumatic Valve and How Does it Work?

A pneumatic valve is a device that controls the flow of compressed air or gas in a pneumatic system. It works by opening or closing the valve to allow or block the flow of air or gas. Pneumatic valves are commonly used in industrial automation systems to control the actuation of different types of machinery.

There are different types of pneumatic valves, each designed for a specific purpose. Some valves are designed to be normally closed, while others are normally open. The operation of a pneumatic valve is typically controlled by a solenoid or air pilot.

Types of Pneumatic Valves and their Applications

There are several types of pneumatic valves, each designed for a specific application. Here are some of the most common types of pneumatic valves and their applications:

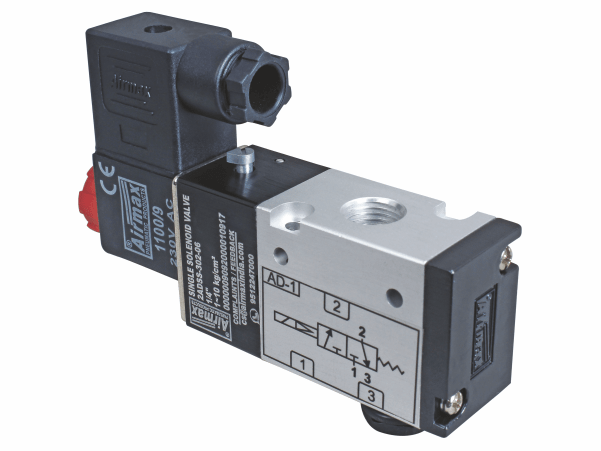

Solenoid valves: Solenoid valves are the most common type of pneumatic valve. They are used to control the flow of air or gas in a pneumatic system. Solenoid valves are typically used in applications where the flow rate and pressure need to be controlled.

Directional control valves: Directional control valves are used to control the direction of air or gas flow in a pneumatic system. They are typically used in applications where the flow needs to be redirected, such as in hydraulic circuits.

Pressure control valves: Pressure control valves are used to control the pressure of air or gas in a pneumatic system. They are typically used in applications where the pressure needs to be maintained at a specific level.

Flow control valves: Flow control valves are used to control the flow rate of air or gas in a pneumatic system. They are typically used in applications where the flow rate needs to be regulated.

Advantages of Using Pneumatic Valves in Industrial Automation

There are several advantages of using pneumatic valves in industrial automation systems. Here are some of the most significant benefits:

Cost-effective: Pneumatic valves are typically more cost-effective than their electrical counterparts. They are easier to install and maintain, and they require less wiring.

Reliable: Pneumatic valves are highly reliable and have a long lifespan. They are less likely to fail than electrical valves, and they can operate in harsh environments.

Safe: Pneumatic valves are safer to use in hazardous environments than electrical valves. They are less likely to cause a spark or explosion, which can be dangerous in certain applications.

Versatile: Pneumatic valves are highly versatile and can be used in a wide range of applications. They can be used to control the actuation of different types of machinery, such as conveyor systems, robotic arms, and packaging machines.

Choosing the Right Pneumatic Valve for Your Application

Choosing the right pneumatic valve for your application is crucial to ensuring optimal performance and reliability. Here are some factors to consider when selecting a pneumatic valve:

Size: The size of the valve should be appropriate for the flow rate and pressure of the system.

Material: The material of the valve should be compatible with the fluid or gas being controlled. For example, valves used in corrosive environments should be made of materials that resist corrosion.

Actuation method: The method used to actuate the valve should be appropriate for the application. Solenoid valves are typically used for on/off control, while proportional valves are used for precise control.

Environment: The environment in which the valve will be used should be considered. For example, if the valve will be used in a dusty or dirty environment, it should be designed to resist contamination.

When selecting a pneumatic valve, it is important to consult with a knowledgeable supplier or engineer to ensure that the valve is appropriate for the application and that it will perform reliably over its lifespan.

In conclusion, pneumatic valves are an essential component in many industrial automation systems. They are used to control the flow of compressed air or gas to actuate different types of machinery. Understanding the different types of pneumatic valves, their applications, and the benefits of using them in industrial automation can help you choose the right valve for your application and ensure optimal performance and reliability.