Hydraulic hose:

Hydraulic i.e. hydra = water = liquid and hose = pipe so the pipe in which hydraulic oil flows is a hydraulic hose. And oil is already compressed as suitable as is used in hydraulic machinery through the high pressure hoses. our topics is hydraulic hose. So lets start knowing more about this.

Hydraulic hose structure:

Natural rubber is used to make the hydraulic hose which makes it absorb free. During the manufacturing process of hydraulic hose many steps are their.

- Firstly, inside rubber tube is made to make the hydraulic hose.

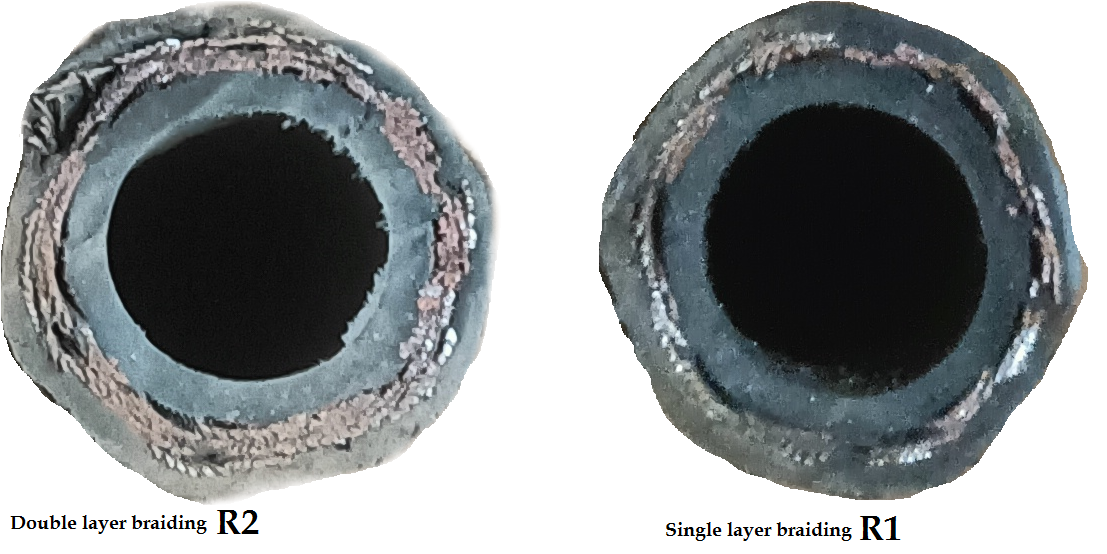

- Secondly, on the tube braiding of steel wire is done, i.e. known by R1, R2.

- Thirdly, after all of this process again outer layer of rubber is extrude along with its length.

And finally hydraulic hose is ready. These kind of structured model makes the hydraulic hose flexible and robust in design.

Hydraulic hose types according to structure:

SAE 100 R1 :

According this standard the pressure sustainability is less compared to other one.

SAE 100 R2:

According this standard the pressure sustainability is more compared to S A E 100 R1 standard.

4SH and 4SP:

According to this standard extra high pressure sustainability existed compared to all other standard.

Hydraulic hose sizes:

Across the globe many sizes of hydraulic hoses is made. But the mostly following sizes of hydraulic hose is made frequently.

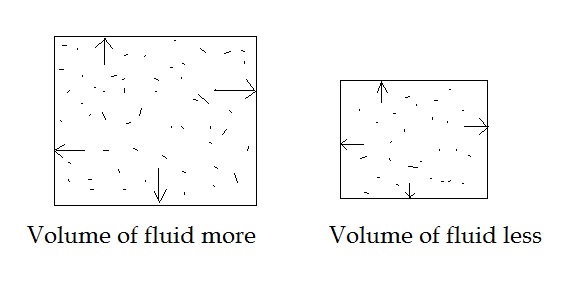

From the above picture shows how the pressure increases or decreases on internal wall of the hose according to the volume increases or decreases respectively. So the less fluid volume means less pressure apply on internal wall of the hydraulic hose and that’s why working pressure value of the hose is more. And more fluid volume means pressure is more on internal wall of the hoses and thus capacity of working pressure decreases.