How Does A Solenoid Valve 2 Way Function in Industrial Systems?

Solenoid valves are essential components in various industries, playing a pivotal role in controlling the flow of liquids and gases. Among the different types of solenoid valves, the 2-way solenoid valve is a fundamental and versatile option. This article provides a brief overview of the functionality of a 2-way solenoid valve.

- Basic Design: A 2-way solenoid valve is designed with two ports: an inlet and an outlet. It’s also known as a 2/2-way valve, indicating two positions and two ports. These valves are commonly used for on/off applications.

- Principle of Operation: When an electrical current is applied to the solenoid coil, it generates a magnetic field that acts on the plunger, which is typically a metal core. This movement either opens or closes the valve, allowing or blocking the flow of media through the valve.

- On/Off Control: Solenoid valves with 2-way functionality are ideal for applications where quick and precise control of fluid or gas flow is required. They can efficiently start, stop, or divert the flow with minimal delay.

- Applications: 2-way solenoid valves find applications in various industries, including HVAC systems, automotive, irrigation, and even healthcare equipment. They are used for tasks such as controlling water flow in a washing machine or shutting off gas flow in a safety system.

In summary, the solenoid valve 2-way functionality simplifies fluid control, making it a crucial component in a wide range of industrial and commercial settings.

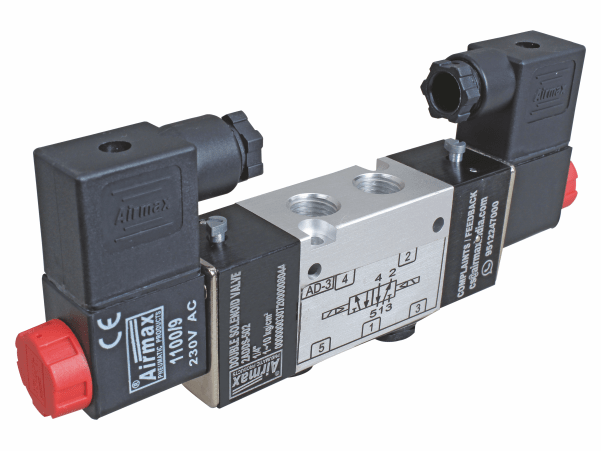

The Core Components of a Solenoid Valve 2 Way

Solenoid valves are essential devices used in a wide range of industries to control the flow of liquids and gases. A Solenoid Valve 2 Way, in particular, is a crucial component in various applications, from irrigation systems to industrial machinery. Understanding its core components is vital for efficient operation:

- Housing: The outer casing of the solenoid valve provides protection and containment for all internal components. It is typically made of durable materials such as brass, stainless steel, or plastic, depending on the application.

- Solenoid Coil: This coil is the heart of the valve. When an electric current passes through it, it generates a magnetic field that activates the valve. Coil materials vary, but they commonly consist of copper wire insulated with materials like enamel or plastic.

- Plunger or Piston: The plunger or piston is moved by the magnetic force generated by the solenoid coil. It controls the flow of the fluid by opening or closing the valve ports.

- Valve Ports: A 2-way solenoid valve typically has two ports: an inlet and an outlet. These ports are where the fluid enters and exits the valve.

- Seals and O-rings: To prevent leaks, seals and O-rings are used to ensure a tight seal between the moving parts and the valve body.

- Spring: In some designs, a spring is incorporated to assist in returning the plunger or piston to its default position when the electrical current is removed.

In summary, a Solenoid Valve 2 Way comprises essential components such as the housing, solenoid coil, plunger or piston, valve ports, seals, and springs, all working together to control fluid flow in a variety of applications.

Principle of Operation: Opening and Closing the Valve

Solenoid valves are pivotal components in various industrial and domestic applications, known for their efficiency in controlling the flow of fluids and gases. The principle of operation behind these valves is based on electromagnetism, offering precise control and reliability. Here’s a brief overview of how solenoid valves, particularly 2-way solenoid valves, function:

- Electromagnetic Attraction: At the core of a solenoid valve’s operation is an electromagnetic coil. When an electrical current flows through this coil, it generates a magnetic field, attracting a ferrous plunger or armature towards it.

- Valve Closure: In a de-energized state (no current), the spring force prevails, keeping the valve closed. This ensures that the fluid or gas flow is blocked when the solenoid is not active, preventing leaks or unwanted passage.

- Valve Opening: When the solenoid is energized by an electrical signal, the magnetic field overpowers the spring force, pulling the plunger or armature towards the coil. This movement opens the valve, allowing the fluid or gas to flow through the valve.

- Keyword Integration: The “solenoid valve 2-way” is a specific type designed to regulate flow in two directions, making it highly versatile for various applications where fluid or gas control is critical.

Solenoid valves, including 2-way variants, are essential components in systems requiring precise and rapid flow control, ranging from water distribution systems to industrial automation processes. Their reliability and efficiency make them indispensable in modern engineering and manufacturing.

Electromagnetic Forces at Play in 2-Way Solenoid Valves

Solenoid valves are essential components in various industries, responsible for controlling the flow of fluids or gases. Among these, 2-way solenoid valves are commonly used due to their simplicity and efficiency in regulating the flow. These valves rely on electromagnetic forces to perform their crucial functions. Here’s a breakdown of how electromagnetic forces come into play:

- Coil Winding: Inside a 2-way solenoid valve, there is a coil of wire wound around a core. When an electric current is applied to this coil, it generates a magnetic field.

- Core and Plunger: The core, often made of ferromagnetic material, intensifies the magnetic field. It interacts with a plunger, which moves linearly within the valve.

- Valve Operation: When the coil is energized, the magnetic field exerts a force on the plunger, attracting it towards the core. This movement either opens or closes the valve, allowing or blocking the flow of the fluid or gas.

- De-energizing: When the electric current is removed, the magnetic field collapses, releasing the plunger. This action returns the valve to its default position.

2-way solenoid valves offer precise control and rapid response, making them ideal for applications ranging from HVAC systems to industrial automation. Understanding the electromagnetic principles behind these valves is crucial for their effective use in diverse industries.

Valve Positioning: Normally Closed vs. Normally Open

When it comes to solenoid valves, understanding the fundamental difference between normally closed (NC) and normally open (NO) configurations is crucial for effective system operation. These two valve positions serve distinct purposes and are essential components in various industries. Here’s a brief comparison:

Normally Closed (NC):

- In the NC configuration, the solenoid valve remains closed in its default state.

- It obstructs fluid or gas flow through the system until an electrical signal is applied to the solenoid, which opens the valve.

- Commonly used for safety applications where shutting off flow is critical in emergencies.

- Suitable for applications like gas pipelines, heating systems, and emergency shut-off systems.

Normally Open (NO):

- The NO solenoid valve is in an open state when at rest, allowing fluid or gas to flow through the system.

- It closes only when an electrical signal activates the solenoid, stopping the flow.

- Ideal for applications where continuous flow is essential and interruption occurs only during specific situations.

- Commonly used in irrigation systems, pneumatic equipment, and certain types of hydraulic machinery.

For your solenoid valve 2 way setup, understanding whether a normally closed or normally open configuration is more suitable will depend on your specific application and safety requirements. Both have their advantages, so choose wisely to optimize your system’s performance.

Controlling Fluid Flow with Solenoid Valve 2 Way

In the world of fluid control, Solenoid Valve 2 Way plays a pivotal role in managing the flow of liquids and gases. These versatile devices are instrumental in a wide range of industries, providing precise control and automation. Here’s why Solenoid Valve 2 Way is essential for fluid flow management:

- On/Off Control: Solenoid valves offer binary control, allowing you to start or stop fluid flow instantly. This makes them ideal for applications requiring rapid response.

- Reliable Performance: These valves are known for their durability and reliability, ensuring consistent operation even in demanding environments.

- Compact Design: Solenoid Valve 2 Way is compact and space-efficient, making them suitable for installations with limited room.

- Energy Efficiency: They consume minimal power, reducing energy costs and environmental impact.

- Versatility: Solenoid valves can handle various fluids, from water and air to corrosive chemicals, making them adaptable for diverse industries.

- Remote Control: With the integration of electronic control systems, Solenoid Valve 2 Way can be operated remotely, enhancing automation capabilities.

- Safety Features: Many solenoid valves come with fail-safe options to ensure fluid flow is halted during emergencies.

In summary, Solenoid Valve 2 Way is an indispensable tool for controlling fluid flow in various applications, offering reliability, efficiency, and versatility in managing liquids and gases. Whether it’s in manufacturing, healthcare, or agriculture, these valves provide the precise control you need.

Applications in Industrial Systems: Fluid Control and Actuation

Fluid control and actuation are critical components in various industrial systems, ensuring the precise management of liquids and gases. One essential element in this process is the solenoid valve 2-way, which plays a pivotal role in regulating the flow of fluids. Here are some key applications and benefits of solenoid valves in industrial systems:

- Automation: Solenoid valves enable automation in industrial processes, allowing for remote control and precise fluid handling. They are used in assembly lines, filling machines, and conveyor systems.

- Liquid Dispensing: Solenoid valves are commonly employed in dispensing machines, ensuring accurate and consistent dispensing of liquids in applications like beverage production and pharmaceutical manufacturing.

- Safety Systems: These valves are vital components in safety systems, where they control the flow of emergency fluids, such as fire suppression systems and gas shutoff valves.

- Chemical Processing: In chemical plants, solenoid valves are used to regulate the flow of chemicals, ensuring the precise mixing of substances and preventing hazardous leaks.

- Water Treatment: Solenoid valves are crucial in water treatment facilities for controlling the flow of water, chemicals, and wastewater, ensuring the purity and safety of the water supply.

- HVAC Systems: Heating, ventilation, and air conditioning systems rely on solenoid valves to regulate the flow of refrigerants and control temperature, optimizing energy efficiency.

Solenoid valves, including the versatile solenoid valve 2-way, are indispensable in achieving efficiency, safety, and precision in various industrial fluid control and actuation applications.

Safety Features and Fail-Safe Mechanisms in 2-Way Solenoid Valves

2-Way Solenoid Valves are essential components in various industrial applications, known for their ability to control the flow of fluids with precision. To ensure reliable operation and prevent potential hazards, these valves incorporate several safety features and fail-safe mechanisms:

- Manual Override: Many 2-Way Solenoid Valves are equipped with a manual override option, allowing for manual control in case of electrical failure or emergencies.

- Position Indicators: These valves often feature visual or electronic position indicators that provide real-time feedback on their status, enhancing operational safety.

- Pressure Relief Valves: To prevent overpressure situations, some solenoid valves include integrated pressure relief mechanisms that automatically release excess pressure.

- Redundancy: In critical applications, redundant solenoid valve setups may be employed to ensure continuous operation even if one valve malfunctions.

- Coil Monitoring: Modern solenoid valves incorporate coil monitoring systems that detect issues like overheating or coil burnout, triggering alarms, or shutting down the valve to prevent damage.

- Fail-Safe Modes: Certain 2-Way Solenoid Valves are designed to fail in a safe position, either open or closed, depending on the specific application’s safety requirements.

Solenoid valves are indispensable in industries such as manufacturing, chemical processing, and oil and gas. Their safety features and fail-safe mechanisms play a crucial role in maintaining process integrity and preventing accidents, making them a vital component in industrial systems. When selecting a solenoid valve 2-way for your application, consider these features to ensure optimal performance and safety.