Machine shops using the five-axis stay way ahead of their competitors. It helps the machinists to manufacture precision machined parts in no time, made possible by 5-axis CNC machining. It has taken over the traditional CNC, 3-axis CNC, and 4-axis machining.

5-axis machining has evolved from its counterpart that is 3-axis. 3-axis had a stronghold in the CNC machining industry for various decades.

The beginnings of 5 axis machining were in 1958. The first machine was built by Cincinnati Milacron and commissioned by the United States Air Force. Due to various advancements in computer systems and design software, CNC designers can turn the concept into reality.

This article will be about the axes, types and applications of five-axis machining.

Axes of 5 Axis Machining

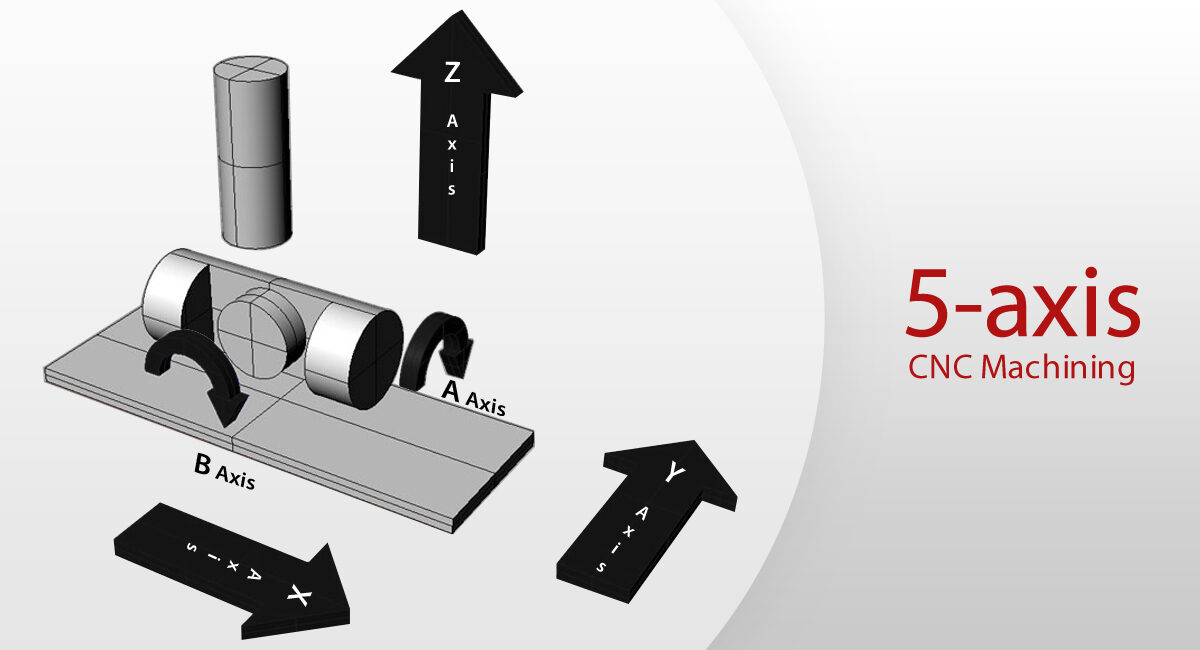

A 5 axis machine operates around these axes:

- X-axis vertical

- Y-axis horizontal

- Z-axis depth

- A-axis rotation at the X-axis

- B-axis rotation at the Y-axis

The axes in the five-axis CNC machining are the paths that tools can move simultaneously. The first three axes are X, Y and Z based on the Cartesian Coordinate System proposed by Rene Descartes in the 1500s.

It gets used to describe three-dimensional space. It gets visually represented as three perpendicular lines that are in different directions. The three lines where it intersects are known as an origin, used as a reference to measure the length of each axis.

The other two axes A and B are tough to visualize. These two axes rotate around the X and Y axes visualized as the inclination of the object moving down with the two axes. Different configuration types are present for these systems and get determined by two of the three rotation axes.

Types of 5 Axis Machining

5-axis machines can help you save time and improve your current process in a variety of ways. 5-axis machines are available in a variety of configurations to meet the needs of the manufacturing industry.

The configuration of the rotary axes is the most distinguishing feature of 5-axis machines. Here are 5-axis divided into three categories:

- Head/Head 5-axis Machines

Both rotary axes on a head/head machine get located in the head. The 5-axis head gets mounted on a gantry that travels above a stationary table holding the workpiece in these machines. Because the head can travel around the part, these machines are ideal for producing large parts. These machines have limited travel in both the tilt and rotary axes due to their design.

- Table/Head 5-axis Machines

One rotary axis is in the table, while the other is in the head in this configuration. The tilting axis is in the head and has a limited range, whereas the rotary axis is typically in the table and has an unlimited range. Because the part gets mounted on the rotary axis, the size of the components it can produce is limited. The ability to continuously rotate the part without fear of reaching a limit is because of this configuration over the head/head configuration.

- Table/Table 5-axis Machines

Table/table machines have two rotary axes in the table. They are table/head machines, have limited tilting axis range but unlimited rotary axis range. This configuration has the little work envelope of the three configurations in this document. However, some table/table machines are fitted with linear motors, allowing them to operate at a breakneck speed.

Primary Industries of 5 Axis CNC Machining

5-axis machining is ideal for applications across various industries that include:

Aerospace Industry: The main reason why 5-axis CNC machines are ideal for the aerospace industry is the limited amount of fixturing required. As the aerospace components are complex and require precision, so 5-axis is a better option. Aerospace components have organic shapes with curves that are ideal for 5-axis machining.

Automotive Industry: The automotive industry requires a high production volume of precision machined parts. Each part needs to be perfect as it needs to get used in vehicles, and it must have a specific tolerance level. They require an advanced process, and 5-axis CNC machining is perfect. Here are some areas in the automotive industry where precision parts get used:

- Engines

- Lighting

- Car parts

- Other necessary parts

Medical Industry: The medical industry only looks for quality and precision. The medical parts have a direct impact on the person’s health if there is a quality issue. So, the machined parts get built by keeping medical standards in mind. The medical parts get used for surgical equipment, for laboratory, for radiology equipment. 5-axis CNC machining can work with various materials to manufacture medical parts with ease.

Energy Industry: The components present in the energy industry get exposed to extreme temperatures. These parts partake in the safety of the site conditions. The 5-axis machining process ensures that these parts get manufactured precisely. It gets completed to the exact specifications that help to maintain safety and functionality.

Conclusion

5-axis machining is gaining popularity over time, and more and more industries are taking advantage of it because of the speed, accuracy and precision it offers. It is all possible with the five axes that are present in 5-axis machining. It is better than 3+2 axis CNC machining as all the 5-axes are operational at the same time. So, improve your machining by implementing a 5axis CNC machining service.