The briquette machine alludes to the biomass fuel apparatus that makes briquettes from biomass squander. They have been used throughout the planet for quite a long time as a result of their indispensable benefits the main biomass hardware producer and provider, gives 3 sorts of briquetting machines to meet various prerequisites for biomass briquettes creation.

Every one of them is generally utilized and famous due to their interesting qualities and utilizations. For numerous kinds of briquette machines, clients can pick a reasonable one as per their creation necessities, shape and size, quality prerequisites, and the utilization of fasteners.

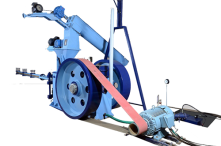

Screw-type

screw-type briquette machine utilizes the drill to press the crude material, with various materials, it very well may be furnished with or without the warming framework to yield briquettes. The warming framework is an uncommon plan for those briquettes manage materials contain lignin, lignin away can be found on biomass. So the warming framework is normally utilized for biomass briquetting. Different materials like coal, charcoal, and so forth folios are constantly required while briquetting with the screw-type briquette machine.

The appropriate material is taken care of to the container and afterward passed on by the screw inside the briquette machine. The pivoting screw takes the material from the feed port and compacts it against a pass on which helps the development of a pressing factor angle along the screw.

Completed briquette yield from the end with stick type Typical cross-area shapes we ordinarily find can be square, round, plum bloom, and so forth.

As the screw briquette machine manufacture works with a pressing factor not unreasonably high, folios are constantly expected to frame the briquette. Outfit with a warming framework will help the biomass material dissolve the inward lignin and go it to a superior folio Moreover, different materials additionally work with this briquette like coal, charcoal, and so forth these materials ought to be all around blended in with the folio to get the briquette structures.

Hydraulic type

water-driven sort works with a pressure-driven siphon station which supplies an extremely huge pressing factor. On account of its high pressing factor, practically every one of the materials can be briquette with this framework.