Today, the majority of the industries are heavily dependent on global supply chains to operate & grow their production. However, things are changing post-pandemic as companies are now leveraging 3D printing to manufacture products. This modern technology has a far-reaching impact on global supply chains, whether automotive, aerospace or consumer products.

Earlier, companies needed to wait for spare parts to arrive from the international market to complete their product lineup. However, it has become possible for large and small-scale companies to speed up their product manufacturing through additive manufacturing.

What is 3D Printing Technology?

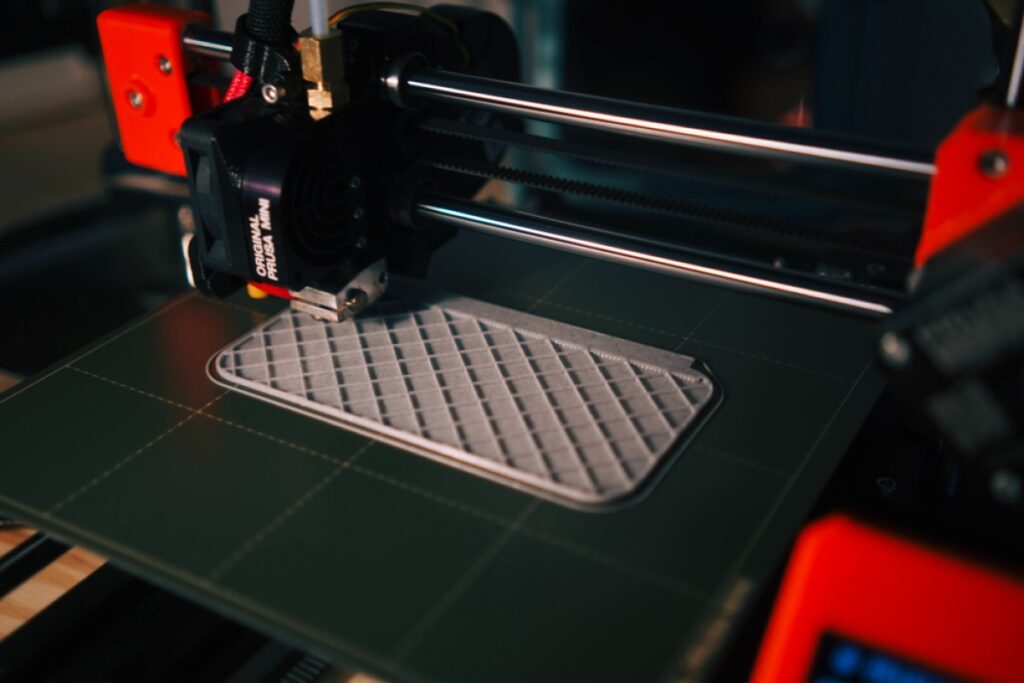

3D printing technology is a modern manufacturing process that utilizes a 3D CAD model to produce a physical object. In this process, a 3d printer creates objects by laying several thin material layers in the desired shape until the design is complete. As it’s an “additive” process, the material wastage is significantly lower than traditional processes.

Photo by Kadir Celep on Unsplash

As the 3D printing technology offers higher durability, strength, and flexibility, supply chains have become more agile and rapid. On this note, let’s explore how three-dimensional printing is transforming the global supply chain.

Decentralized Production

As this technology is portable and flexible, manufacturers can use it anywhere and meet their production goals. Leveraging 3D printing, the trend of on-demand manufacturing is booming across industries, and it’s allowing companies to have good-quality local production. After this advancement, supply chains have now become more decentralized and on-demand. As a result, companies don’t need to manufacture components in bulk, reducing massive money & resources wastage. Decentralized production is a boon as no one needs to rely on third-party to grow their business.

Quick Personalization

Compared to traditional supply chain technologies like CNC machining, 3D printing offers much faster product personalization. Earlier, organizations had to place orders in bulk in case they needed personalization. However, as this new technology can efficiently operate on a smaller scale, customization has become more accessible for all companies. This optimization results in a more agile production ecosystem. As design communication has become much more accessible across the supply chains, we will see more innovative product manufacturing in the future.

Mitigated Complexity

Regardless of any industry, the supply chain is a complex aspect. The management difficulty only grows with time as more vendors on-board it. 3d printing services can help vendors, suppliers, and OEMs to reduce the supply-demand complexity with ease. Instead of relying on distantly located companies, businesses can use local 3d print services with a faster turnaround time. This overall optimization of supply chains improves a business’ time-to-market.

It Boosts Resource Efficiency

Besides being cost-effective, 3D printing is also an environmentally friendly technology that helps manufacturers with higher resource efficiency. As this method causes minimum material wastage with less emission of harmful gases, it’s the future of the mainstream supply chain. Thus, 3D printing will help supply chain vendors reduce their carbon footprint and make the surroundings greener in the long run.

Reduced Logistics Expenses

Logistics is a considerable overhead for companies working in a chain to operate their production. As 3D printing lets them produce 3d printed parts with a shorter turnaround time, logistics expenses decrease. As a result, OEMs can save substantial capital in logistics and monitoring. In addition to logistics, this tech also helps manufacturers save money on warehouse management.

Future Of 3D Printing in Supply Chains

This technology will disrupt the entire supply chain much sooner than we think. Whether it’s on-demand manufacturing, in-house printing, or better design communication, these future-focused elements will make the supply chain more agile.

Photo by Minkus on Unsplash

With growing popularity, several 3d print companies in Melbourne, Sydney, and other places now offer professional 3D printing services. As a result, a business can kickstart its production using on-demand manufacturing and get ahead of the curve.