Multiple industries choose aluminum for the parts they use in-house or in connection with the consumer goods they manufacture. That makes sense considering this particular type of metal has amazing qualities, including strength, versatility, and prolong resistance to corrosion. This is why the demand for professional aluminum CNC machining continues to rise.

With CNC machining services, experts can produce all kinds of parts and components used in the health care, automotive, consumer electronics, and aerospace industries. One aspect of this metal that makes it unique is the different available grades. This diversity is why aluminum is so in demand. Manufacturers also appreciate the workability of this metal.

Top Benefits of Traditional and Custom Aluminum Machining

To gain a better understanding of why aluminum is the number one metal used for machining, consider the top benefits.

-

Machinability

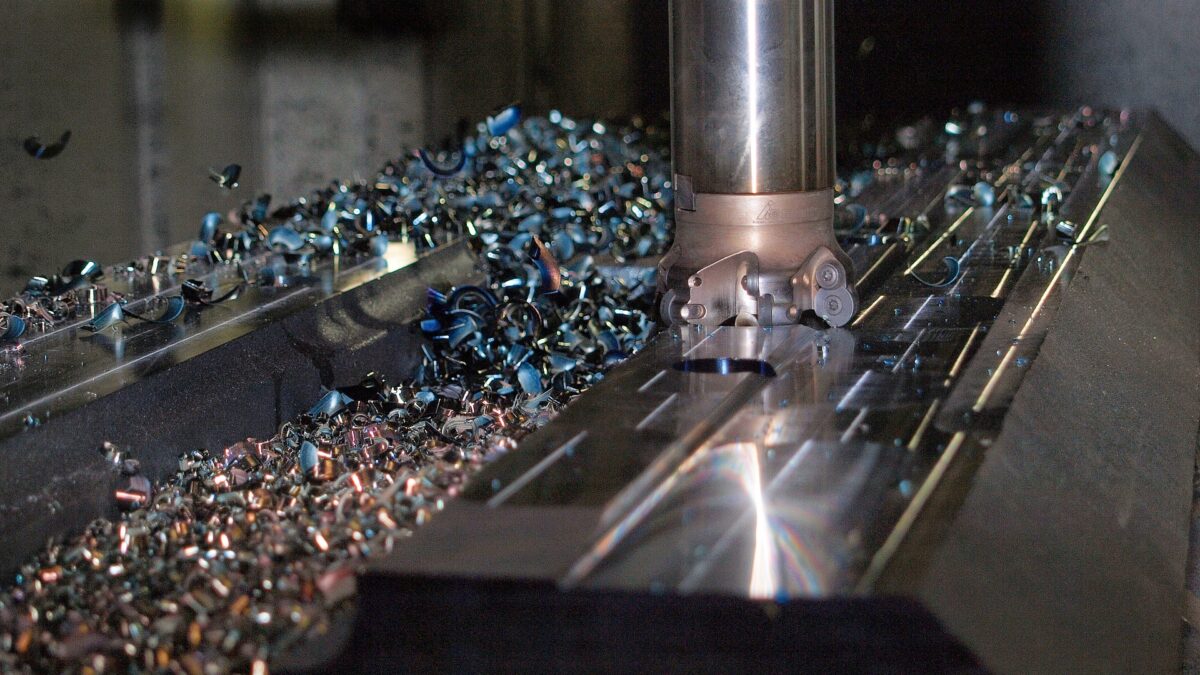

The primary reason engineers go with aluminum for machined parts and components has to do with easy machinability. Sure, the ease of CNC aluminum machining makes work easier for the operator, but at the same time, it benefits the customer. It doesn’t take much time to create an aluminum part or component in the desired shape. That means customers receive a superior quality product much faster than if they’d chosen a different metal.

Something else worth noting is that CNC machining services save the customer money. The combination of little labor involved to produce a precision product and less required operating time makes this a cost-effective solution. Also, because the cutting tool doesn’t cause deformity of the workpiece, the machine can meet tighter tolerances.

-

Corrosion Resistant

A lot of businesses prefer aluminum since it’s resistant to corrosion. So, for parts or components exposed to the elements, this is a nice bonus. Keep in mind that the exterior of aluminum does oxidize over time. For products that need to withstand damage from certain chemicals or certain types of corrosion, custom aluminum machining is ideal.

-

Recyclable

This is yet another reason why so many industries choose aluminum for CNC machining. Today, an increasing number of companies make decisions to help protect the environment. As a recyclable material, they can have this material turned into many different products if needed. What they don’t use can go to a recycling facility.

Additional Benefits of Custom Aluminum Machining

Machining this material offers many additional benefits. For instance, it has a high strength-to-weight ratio. Although lightweight, aluminum can hold its own. This makes it a perfect choice for automobile shafts and airplane fittings.

Aluminum also boasts excellent electrical conductivity. For companies that manufacture electrical components, this is essential. Turn to a Reputable Source for Aluminum CNC Machining.

For premium parts and components, businesses can always rely on us at Promark Tool & Manufacturing Inc. We provide comprehensive solutions, all affordably priced. Contact us today to discuss your needs.