Metal Laser Marking, also known as GMAT, is a relatively new method of marking heavy and oversized items with lasers and then having them engraved or sprayed onto the metal. It’s not a new idea. However, it is still relatively expensive and somewhat of specialist skill. It is mainly used by the industries and businesses that deal in substantial and heavy goods. A laser marking system like this can be used for personal identification to shipping to machine guns, and even bulletins. With such a wide variety of uses, it is only reasonably sensible that there are various companies and people that provide this service. So it is worth researching which companies or businesses you might already use before committing to one particular provider of this technology.

This is a perfect time to invest in a high-quality laser marking spray as technology moves forward at a breakneck pace. Suppliers of this equipment have seen the demand for metal laser marking equipment grow tremendously, so they are constantly upgrading and producing ever more advanced products to meet the needs of their customers. If you were to take a little look around your local area, you would notice that almost every hardware store or even the larger supermarkets now stock a range of these machines. This is great news for consumers, as this means that you can be marking metals almost anywhere. As technology moves forward, these products are also likely to become less expensive, as companies are forced to reduce their prices to stay ahead of the competition.

The first stage of any metal laser marking job is pre-drilling the target surface. This makes sure that the coating applied will be of the right thickness, and this also helps ensure that no errors are made during the process. Next, the laser marking machine is loaded into the sprayer. This generally requires a single short burst of compressed air before it can be deployed. After this has been done, a cloth roll is placed on top of the metal sheet, and a laser-guided “beam” is aimed at the sheet metal.

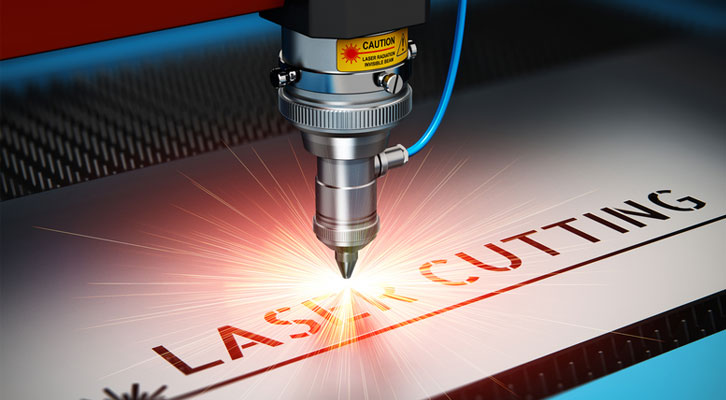

A co2 laser or a similar light-emitting diode (LED) is then directed at the metal. This emits a very intense beam of light which can mark through many layers of thick metal quickly and with a high level of accuracy. Some of these laser marking metal lasers are automatically guided through the sheet metal by their computerized software, while others are manually aimed. These types of co2 laser marking machines are much more expensive than their automatic ones, however, and are rarely used by companies outside of the scientific and industrial sector. They are most commonly found in government labs, training facilities, and military organizations.

The next stage of the process is the spraying of the metal with a color laser marking paste. This is often referred to as a ‘target’ or ‘indicating’ layer because the text or other information you want to be printed is written on this layer before the metal laser marking machine can proceed. The target layer must be highly durable and resistant to corrosion before the machine can work. Once the indicating layer has been applied, you can either leave it to dry overnight or hand push the laser metal marking machine into the targeted spot. If you do not want any mistakes, the operator should ensure they don’t touch the paint or ink while the device is working.

The metal laser marking machine will apply a stencil to the desired location. This is typically a high-quality metal name tag – but may also be encoded to include a company logo, name of the receiver, and even a photo of the ‘person’ who will be receiving the package. The laserjet machine will then fire a continuous stream of laser at the stencil. This process is usually very fast, allowing marking to occur within a few seconds.

As mentioned earlier, when you are considering purchasing a laser engraving service in USA, you must be sure that the company offers a competitive quote for this service. The cost of this type of service is likely higher in USA compared to laser metal marking machine prices in the West. This is because laser engraving machines in the West often offer engraving in multiple colors (although this is not always the case), and the cost per piece increases as each color is used.

To get the best value for money, you should take the time to choose a supplier that specializes in metal laser marking spray application in USA. This way, you are guaranteed to receive a high-quality product, and the company will be able to optimize its pricing to suit your individual needs. Ensuring that you have all of your requirements covered from start to finish ensures that you can quickly make the transition to new business processes, providing you with the result of a professional-looking label that accurately reflects your brand. Choosing the right supplier from the correct location means that your product will be delivered in the best possible condition, making it more likely to retain its value and meet your exact requirements moving forward.