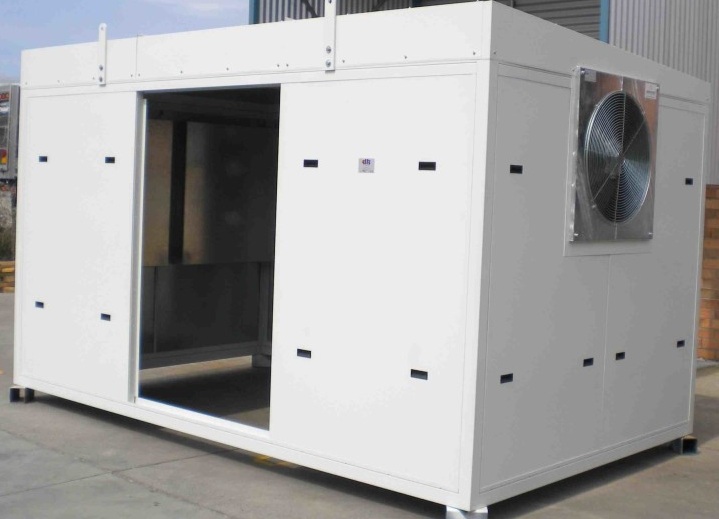

All machines that produce more noise than the legal limit must be contained in an acoustic enclosure. One of the key reasons for Machine enclosures with built-in acoustic control is that there are environmental protection industrial regulations governing the noise level for machines. Machine enclosures are custom-made to fit the machine’s dimensions. The position of the machine and its surroundings are crucial factors to consider since they may need weatherproofing the exteriors. Certain characteristics are present in the heavy machine enclosures. Such as :

- Pipes, wires, and cable cutouts

- Light and visibility are provided through double-glazed glass windows. If necessary, this can be wire treated.

- Noise leaking is prevented by doors with a gasket seal.

- Louvered air valves for ventilation with acoustic treatment

- Removable panels for machine repair and maintenance, particularly if the enclosure is tiny.

- The cage has a 300 LUX illumination intensity, which allows for plenty of visibility within.

Acoustic enclosures are made specifically for heavy industrial equipment that produces a lot of noise. These enclosures serve to soften the noise and maintain it within acceptable boundaries. These acoustic enclosures have been scientifically constructed and are galvanized for long-term endurance. These are completely certified systems for power generation equipment acoustic treatment. Compressors and cogeneration units with strong reverberation and sound resonance are typically housed in acoustic enclosures. Diesel generators and other heavy machinery can also be stored in these acoustic enclosures.

Specification for Acoustic Enclosures

- Silencers are used to mute the air inlet.

- The container is fire-resistant.

- Controlling the temperature and humidity within

- Soundproof door with gasket seal and specific access hinges

- Internal illumination and an electrical connection are included.

- Panels that can be removed if necessary

- For visibility and external light, double-glazed windows are used.

The enclosure is made to order, according to the unit’s specifications. The ISO acoustic enclosures come in three sizes: 20 feet cube, 30 feet cube, and 40 feet cube. For a Standard ISO size enclosure, we have a quick turnaround time of 4-5 weeks. It is possible that a custom-sized enclosure will take a bit longer to arrive. Our acoustic enclosures are composed of high-quality materials, making them long-lasting and reliable.

Factory Noise Control

Noise attenuation criteria or noise effect at a crucial receptor point or at the property line are generally used to determine factory non-occupational environmental noise compliance. Construction activities, manufacturing/production operations, or upset condition alarms could all be sources of noise. The agencies that regulate this form of noise are usually local, but this varies by state and municipality. Ordinances like these are common:

- Allowable noise levels during the day and at night

- Areas are divided into three categories: residential, business, and industrial.

- Decibel levels that are deemed appropriate for each category

Factory Noise Control Techniques

In a controlled environment, noise attenuation is performed by lowering the intensity or volume of sound. In factory environments, there are a variety of noise reduction measures that can be used. Noise abatement equipment can be used to reduce the environmental impact of industrial processes such as vent blow-offs, rooftop fans and HVAC equipment, chillers, cooling towers, oil and gas building ventilation systems, power gen engines, and other noise-generating processes. One of the most successful and rational approaches to Factory Noise Control is to implement systems that reduce noise from the start, such as:

- Industrial Exhaust Silencer

- Noise Control Enclosures

- Duct Silencer

- Acoustic Building Ventilation Systems

- Acoustic Blankets/Wraps

- Duct Lining

- Damping

Noise reduction from chutes, hoppers, machine guards, conveyors, panels, and other sources

- Selecting Efficient Equipment

Noise reduction is aided greatly by choosing efficient fans, compressors, PD blowers, and engines.

- Adjusting Fan Speed

Because fan noise is directly proportional to fan speed, small changes can have a big impact.