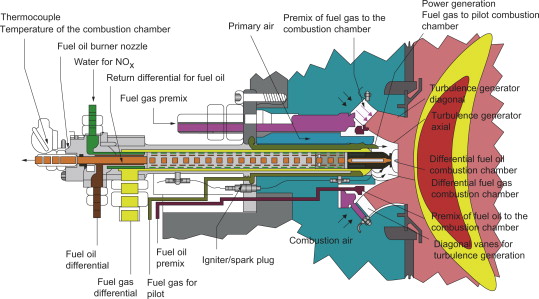

A fuel nozzle for a gas turbine engine injects a liquid fuel passage from a fluid fuel passage in the swirler vane. Airflow over the swirler vane atomizes the liquid fuel-flowing process to form a fuel-air combination. The fuel nozzle overcomes the need for a conventional air blast atomizer.

One of the leading causes of damage to gas turbine hot section elements is imbalanced fuel distribution due to dirty or defective fuel nozzles.

Having more fuel flowing to one nozzle & less fuel to another will also become the reason for more NOx & CO emissions because of hot spots and cold spots simultaneously existing in the combustion section.

Those exact hotspots reduce the creep life of the combustion liners, transition pieces & turbine nozzles, and blades. These issues can reduce by the careful refurbishment of utilized nozzles.

Why are Fuel nozzles essential?

Every combustion chamber is linked with a fuel nozzle that emits the metered amount of the needed fuel into the combustion liner. Fuel nozzles are utilized in gas turbines or burning gas. The fuel nozzle operation is to distribute the gas fuel into the combustion liner’s reaction zone in a way that fosters uniform, rapid & complete combustion.

Gas fuel enters the fuel nozzle assembly via the fuel gas link with flange & is routed through the nozzle inside passages to orifices located in the gas tip.

Here’s one more tip to consider when removing fuel nozzles. Suppose you have an issue or swearing problem with your engine (or just want to be careful). In that case, you might want to consider marking the position of every nozzle relative to the engine for troubleshooting functions. “We usually clean the nozzles coming in before passage checking them,” shares Don Beaulieu, shop manager at Heritage Turbines.

“But if a client is having an issue and desires a pre-flow check, they can mark the positions the fuel nozzles are erased from before sending them in. We can then do a quick pre-flow check and let them find any discrepancies.”

Fuel nozzle removal is spelled out in the maintenance & managed manually. You erase the safety wire, remove the bolts (or nuts in a few newer engines), and slide the transfer tubes out (i.e., into the adjacent fuel nozzle adapter). Erase the nozzle & sheath assemblies from the engine.

A care guide must be used whenever handling fuel nozzles in the removal procedure. Be careful while removing the transfer tubes and not to damage them.

Functions of Fuel nozzles;

The objective of using a nozzle is to mainly get very highly rated at the expense of the pressure energy of the gas. This boost velocity will propel the turbine at a very extensive speed. That high speed, in turn, can be utilized for various purposes.

The fuel & air after combustion passes to the turbine and the fuel nozzle. The gas gets expanded in the gas turbine. Nozzle transforms the pressure energy into kinetic energy. i.e., pressure decrease and velocity upgrades. The increased velocity generates thrust force (F=m*a). The generated thrust force assists in moving the system forward.

Handling damage;

“Whether mechanics are performing a few initial cleaning processes themselves or preparing the hardware for return to the manufacturer for any kind of the service, extra care measures should be taken when handling this part.

The fuel nozzle tip & any sealing surfaces or threads are prone to harm with rough handling. Packaging is very essential. Great care & handling can have repair costs and possibly be the difference in mid of a salvageable part & one that becomes scrap.”

Salvaging damaged nozzles;

With streaky sprays that can’t be repaired by simple cleaning, fuel nozzles may require a new nozzle body. They might need refinishing the nozzle orifice, depending on whether there is any internal or external problem and how severe the issue is.

It might be possible to restore the nozzle finish with patience. It can generally refinish any surface with scratches under five-thousandths of an inch.

If the problem is in the orifice angle location, however, you might not be able to save it. By the time you erase scratches, etc., the angle might be locally altered & the final orifice diameter is opened up beyond blueprint limits.

A new life for turbine fuel nozzles;

Manufacturers do not usually spring to mind when speaking of competitive aftermarket repair & overhaul services, but that has changed dramatically in this industry over some years.

The sharp downturn was seen while the early 1980s forced aircraft manufacturers to look very seriously at ensuring competitive aftermarket services. This is particularly great for many of the manufacturers of turbine fuel nozzles. Nozzle blades are static & hence much more helpful to heat stresses.

Usually, they are hollow, and fresh air from compressor stages is ducted via them. The first level is rotating turbine blades made of a different material. It doesn’t need refrigeration at all.

Connect with Prismecs and get all relevant information and services for fuel nozzles. You can connect through this number: 1888 7747632

What are turbine nozzles?

All gas turbine engines have a nozzle to generate thrust, conduct the exhaust gases back towards the free stream, and set the mass flow rate via the machine. The nozzle sits downstream of the gas turbine. A nozzle is a relatively simple to adjust device, just a specially shaped tube through which hot gases pass.

What are fuel nozzles?

An automatic fuel nozzle is utilized to fuel vehicles at gas stations & fuel depots. The fuel loading diesel nozzle stops the flow of transferring gas automatically.

What is the use of a nozzle?

A nozzle is usually a pipe or tube of varying cross-section allocation. It can be utilized to direct or modify the passage of a fluid (liquid or gas).

Nozzles are frequently helpful in controlling the rate of flow, speed, direction, mass, shape, or the pressure of the stream that occurs from them.