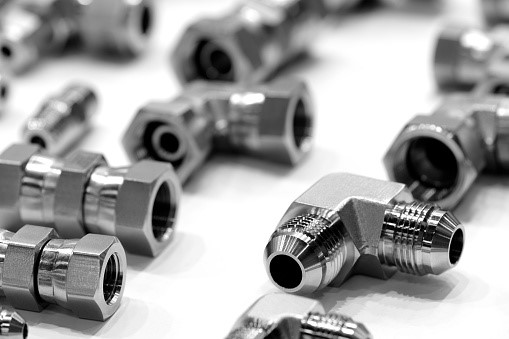

A fastener is a hardware device used to form a joint to hold objects together mechanically. The fasteners have mechanical things by creating either a non-permanent or permanent joint. A non-permanent joint enables engineers to efficiently join corners together and conveniently separate them on requirement without damaging the material. Thus, it is crucial to determine the best fasteners manufacturers and suppliers. But before assessing the manufacturers and suppliers, it is essential to be familiar with different types of fasteners.

What are Fasteners?

Fasteners are an efficient choice of tool used for forming joints. This does not imply that a fastener is used for weak purposes. A fastener can easily be used in joints that undergo severe stress conditions. This means that the fastener is a suitable choice for both permanent and non-permanent joints alike. Fasteners are generally categorized into two categories, namely permanent and non-permanent fasteners. Reliable fasteners manufacturers and suppliers must possess quality permanent and non-permanent types of fasteners.

Types of Fasteners

The permanent and the non-permanent type of fasteners are crucial in every construction. This is because a structure requires both joints to be efficient and effective. Both permanent and non-permanent types of clasps are discussed below:

- Permanent Fasteners- These are used to form a permanent joint at the required position. Since permanent joints have to withstand different conditions, these fasteners are manufactured keeping durability in mind.

- Rivets- This is a permanent type of fastener. Its body consists of a cylindrical shaft called the rivet pin with the rivet head present at one end.

- Nails- A nail has no threads on its body. It has a long continuous metal body, and it is designed to provide strength and support to joints for long periods.

- Non-Permanent Fasteners- These are used to form a temporary joint. Such fasteners are manufactured so that they are easily removable and re-usable.

- Nuts & Bolts- This is a temporary type of fastener. Nut and bolt are used collectively to form a quick joint. Bolts are long metal objects with grooves at one end and ahead at the other. These grooves are called threads. A nut is a small mechanical fastener with a hole in the centre. The spot of the nut contains threads similar to that of a bolt. These threads perfectly fit into each other to provide a temporary solid joint.

- Screws- A screw is similar to a bolt, except it contains a helical threading ridge at the end. The quality of a fastener is determined by the fasteners manufacturers and suppliers.

Manufacturers and Suppliers

Pins are considered the building blocks for engineering. This signifies the importance of the products. Thus, a project needs to choose the correct fasteners manufacturers and suppliers. Some factors should be assessed in detail. These factors are discussed below:

- Material- The material of a fastener determines its strength and durability. Therefore, fasteners manufacturers and suppliers must provide pins in various materials such as Steel, Brass, Aluminium, and so on.

- Coating- The coating makes sure that the fastener is corrosion resistant. Hence, durable for long periods.

- Type- There is a wide variety of fasteners used by engineers to achieve different types of joints. Hence, all the varieties of pins must be available.

Size- Mechanical structures require support at various positions. This requires different sizes of fasteners. So variation in sizes of other pins must be available.

Now you are aware of the fact that fasteners are a crucial element in the world of engineering. The fastener is the basic hardware that forms the foundation for today’s most complex and marvellous engineering creations. Fasteners possess great importance to engineering purposes. Thus, coated fasteners must be available to the fasteners manufacturers and suppliers which you can visit any time you need these.