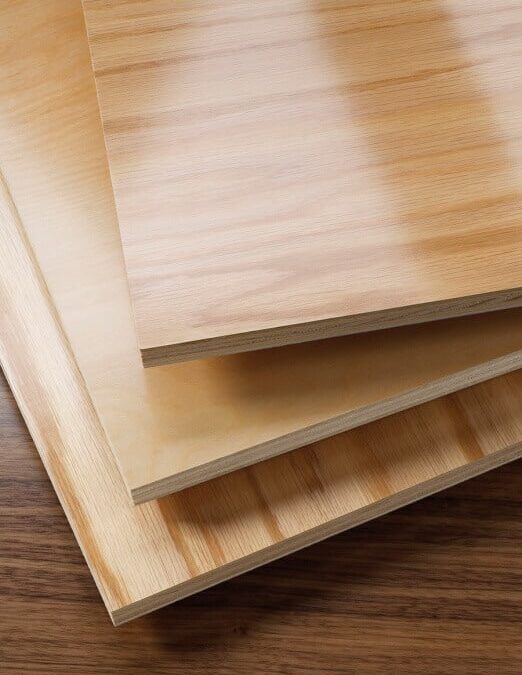

Plywoods, sometimes known as ply, are a type of engineered sheet timber that is frequently used in buildings. It is created by adhering three or more thin wood veneer layers, or “plies,” to one another to create a broader, flat sheet. Plywood is significantly more expensive than substitutes for raw wood like MDF (multi-density fiberboard). Plywood is still significantly less expensive than real wood, though.

High strength and stability are qualities of plywood. Because plywood in India has a strong industry, it is simple to select the best supplier there. The thin layers of wood veneers that make up plywood are assembled and joined with strong adhesives to create the final appearance.

Why is good quality so expensive?

Plywood made from the wood core is more expensive and premium than any other plywood type available in the Indian market. Plywood’s face is made from premium wood. Most face veneer used in plywood in India is imported from other nations. D is the most affordable option, while A has the highest cost and performance.

Plywood rated A has a surface that has been sanded smooth and is knot-free. To allow the veneer to be painted, any wood flaws have been filled with synthetic material. Cabinetry or cabinet doors work best with A-grade plywood.

A plywood product’s best quality has always been ISI-certified. Commercial or MR Grade Plywood is defined by IS: 303, and Marine or Waterproof Plywood is defined by IS: 710. Whenever there is an ISI mark, always look for the CML number.

Modern plywood can bear a lot of in-service stress (from all directions) for a longer period of time since it has this consistent strength. It is, therefore, a more robust option than both solid wood and other hardwood goods.

What happens when choosing poor-quality plywood?

- Poor calibre Plywood can wrap around and take on bizarre shapes that ruin the aesthetic of a carefully designed interior. When plywood wraps, there is no other option but to replace it entirely because it cannot be fixed to resume its original function.

- Termite and Insect pest Attacks – Panels of poor quality are vulnerable to termite and borer attacks, which result in the formation of mud tunnels. No matter how many measures you take to prevent the infestation, if your plywood is not termite or beetle-proof, it will inevitably happen regardless of how much care you take to prevent it. In addition, poor-quality plywood frequently has voids between the layers, which makes them vulnerable to bug infestations.

- Structural failure or delamination – As we all know, plywood is made of layers of core and frame veneers that are alternately glued together. The manufacturing process’s most crucial step for figuring out plywood’s endurance factor is this one. Delamination occurs primarily when the adhesive used to hold the layers together fails due to poor quality. As a result of the layers’ internal curling and twisting, the entire construction has a spongy, wet feeling. This issue frequently affects low-quality plywood because the low-quality adhesive is used. In addition to weakening the strength, this reduces the temperature resistance.

How do dealers compromise on the prices?

There are frequent promotions and discounts offered by a brand that homeowners may not be aware of. Here, dishonest dealers may offer plywood at the original price to maximise profits. As a last resort, they might sell lower-quality plywood to customers fraudulently by taking advantage of consumer ignorance.

The rating of plywood that is handed over becomes even more difficult to determine if the carpenter begins working on it right away. Therefore, homeowners must understand the fundamentals of distinguishing between the various grades of plywood. Only 30% of homeowners are thought to get the kind of plywood they want. The homeowner is frequently duped regarding the grade or type of plywood the customer wants.

How to get quality plywood furniture for a reasonable price?

Quality plywood furniture at a reasonable price is easily accessible on the internet today. There are various options for Plywood sheets online in various colours and sizes. Good quality is so rare to find, but it is out there!

What steps can you follow to choose good-quality plywood in India?

-

Choosing the proper grade –

Take a look at the type of construction work when deciding on the ideal plywood grades in India. Strong plywood with high wear resistance is required for heavy-duty construction work.

-

Keep an eye out for the ISI mark –

If you want to guarantee the durability and high quality of constructed objects, make sure to buy plywood that bears the ISI mark.

-

Choose low-emission plywood –

In India, make sure to choose environmentally friendly plywood.

-

Search for plywood that isn’t stained –

Because the stains hide any imperfections in the grain, you might not notice them in stained plywood. Decide to purchase unstained plywood and have it stained just before fabrication if you want the best plywood possible. This approach is great because it will assist you in finding the ideal stain that will perfectly complement your home’s interior design.

-

Request a sample –

This will allow you to determine whether the plywood is a full panel or a full core. The sample piece can be used to determine the type of wood core that is being used, and you can check the plywood’s quality by seeing how well it holds nails.

Conclusion

The right price for the right quality becomes very essential in these expensive times be it any furniture you want to get made. Ordering furniture online has become a trend these days where you can deal with the dealer directly and get things for cheaper with the same original quality.

Plywood can be ordered with discounts and offers and one can find the best quality plywood sheets online as well.