SIL certification is a voluntary process by which a company or individual can have their product or service certified as conforming to the requirements of a standards organization. The SIL certification of rubber lined valves is not required by law, but it may be required by some companies in order to do business with them. It is also a way for a company to show that they are committed to providing safe and high-quality products. In this blog post, we will explore what SIL certification is and how it applies to rubber lined valves. We will also discuss why some companies require this certification and what it means for the consumer.

What is SIL certification?

SIL certification is a voluntary safety certification program developed by the International Electro technical Commission (IEC). It is widely recognized in the process industries and is often a requirement for tenders and insurance purposes.

The IEC 61508 standard covers the general principles of functional safety for electrical, electronic and programmable electronic safety-related systems. The standard was first published in 1998 and has been revised several times since, most recently in 2010.

To achieve SIL certification, a product must undergo rigorous testing to demonstrate that it meets the requirements of the relevant SIL standard. The testing is carried out by an independent, accredited test laboratory.

SIL certification provides reassurance that a product has been designed and manufactured to a high standard of safety and quality. It is an important factor to consider when selecting products for use in potentially hazardous applications.

What is a Rubber lined valve?

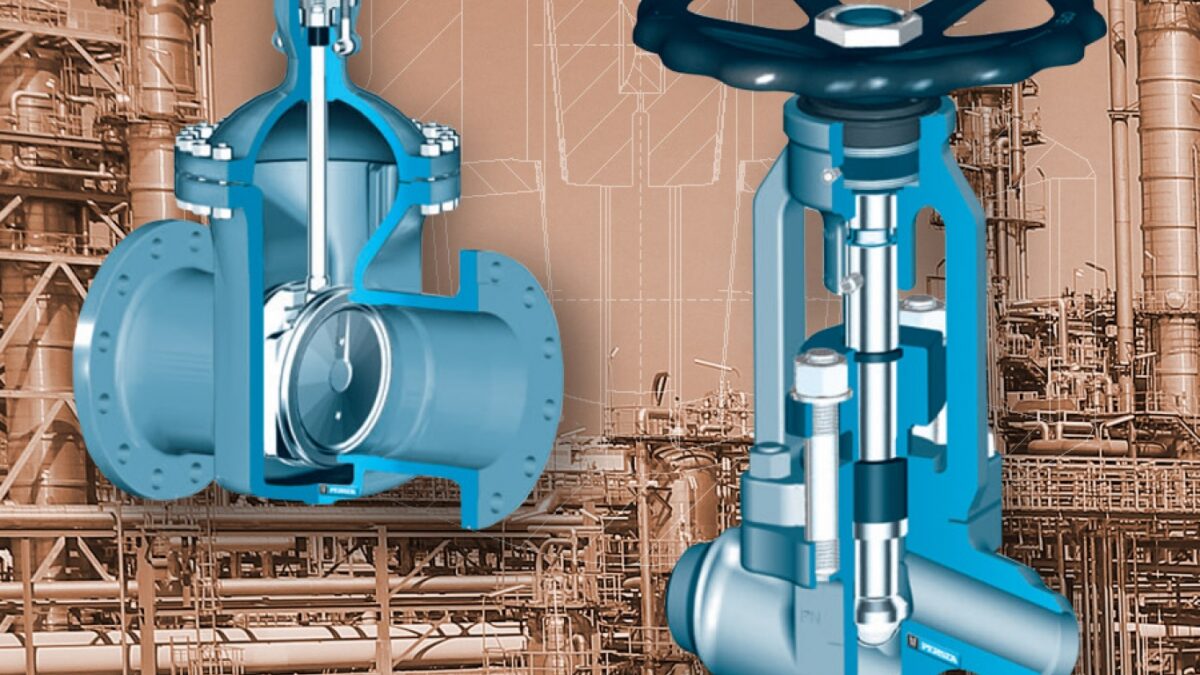

A Rubber lined valve is a valve that has been lined with a layer of rubber in order to improve its durability and performance. The rubber lining protects the valve from wear and tear, and also makes it more resistant to chemicals and other corrosive materials. Rubber lined SIL certified valves are often used in industries where there are high levels of stress on the equipment, such as in the oil and gas industry.

The benefits of SIL certification for Rubber lined valves

SIL certification is an important safety certification for rubber lined valves. It stands for Safety Integrity Level and it is a measure of the reliability of the safety function of the valve. The certification ensures that the valve will perform its safety function in a reliable manner over its entire lifetime.

The benefits of SIL certification for rubber lined valves include:

-Increased safety: The certification means that the valve has been designed and manufactured to a high standard, which increases its safety.

-Reliability: The certification means that the valve is more likely to be reliable over its lifetime.

-Peace of mind: Knowing that your valve has been certified to a high safety standard can give you peace of mind.

How to get SIL certified

If you want to get SIL certified, there are a few things you need to do. First, you need to make sure your company is registered with the CSIRO. Second, you need to have a quality management system in place that meets the requirements of ISO 9001:2008 or equivalent. Third, you need to submit an application to the CSIRO for review and approval. Finally, once your company is approved, you will be issued a certificate of registration.

Conclusion

SIL certification is important to consider when rubber lined valves are being used in a process. The certification helps ensure that the products will perform as intended and help keep people safe. There are different levels of SIL certification, so it is important to choose the right one for the application. With the proper level of SIL certification, you can be sure that your process is running safely and smoothly.