Component or product production is the most common application for SS 347 Sheets & Plates. It’s an austenitic stainless steel with a chromium microstructure that can withstand harsh environments and resists all oxidising agents, preventing corrosion. Cold hardened SS 347/347H Sheets and Plates feature the highest amount of ferrous for outstanding strength. It prevents intergranular corrosion and stress rupture cracking in high-compact applications.

SS 347H Sheets and Plates have a greater carbon and cadmium concentration than SS 347. In high-temperature situations, it’s designed to give greater creep resistance and thermal stability. SS 347H Sheets and Plates have a high strength due to the ferrous content and are perfect for building tanks and components for high-compact service. It is resistant to erosion, abrasion, and sulfidation corrosion.

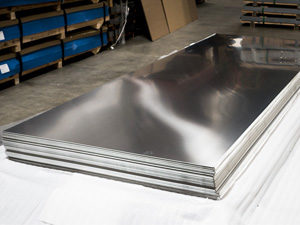

These Stainless Steel 347 Sheets are distinguished by their superior polish, compact designs, solid construction, corrosion and chemical resistance, and durability. On Stainless Steel 347 Plates, solution treatment is carried out at temperatures and times that offer the appropriate properties, and the material is then cooled to avoid 475-degree C embrittlement. Stainless Steel 347 Coils are well-suited to a variety of applications in industries such as Chemical Processing, Oil & Gas, and Marine environments, offering more strength than both austenitic and 22 percent Cr steels.

Stainless Steel 347H Sheets have pitting resistance, high strength, SCC, erosion weathering and oxidation fatigue resistance, crevice rust resistance, and potent weldability. Stainless Steel 347H Plates have a microstructure that contributes to its high strength and resistance to stress corrosion cracking. In the chemical process sector, stainless steel 347H Coils and Stainless Steel 410l Plate are commonly used in nitric acid processes, polypropylene manufacture, caustic evaporators, and organic and fatty acid handling equipment. Stainless Steel UNS S34700 Sheets & Plates has a lower coefficient of thermal expansion and heat conductivity than austenitic steels, and can tolerate temperatures of up to 300°C.

To verify product quality, many tests are used. These tests are used to determine the quality and characteristics of Stainless Steel 347H Plates. To assure the product’s quality, positive material identification tests, flattening tests, micro and macro tests, hardness tests, flaring tests, mechanical testing, pitting resistance tests, and other tests are conducted. These examinations are conducted under the supervision of trained and experienced specialists. Quality assurance certificates are attached after the product’s quality is checked on numerous aspects.

To get further details know more at BhagyaLaxmi Industrial as they are one of the leading and well-known SS 347H Plates Supplier and also other material products. At BhagyaLaxmi Industrial, they are developing only the finest quality of Stainless Steel 347H Plates under the strict guidance of our professional experts. For the fabrication of SS 347H Plates, they use only premium quality raw materials. And before that, quality experts check the quality of the collected raw materials. Only workers and engineers are making use of the raw materials for product development.