Technology is driving changes across all areas of society. Not only we increasingly use it but rely on it for various purposes of life. We also find our workplaces are digitally evolving with more process now taken using technology. This is called fourth industrial revolution.

Due to advancement in 5G technology, we are in the middle of revolution especially we produce the product, manufacture, and do operations. Organizations are facing challenges to adapt themselves in order to survive.

IR 1.0 & IR 2.0 emphasized on mass production while IR 3.0 further enhanced production through automation in order react faster according to customer needs. IR 4.0 emphasizes on IoT which enable real time monitoring decision making. This also involves many tasks which were previously done by human are now fully automated with help from artificial intelligence and big data.

Why it is Important?

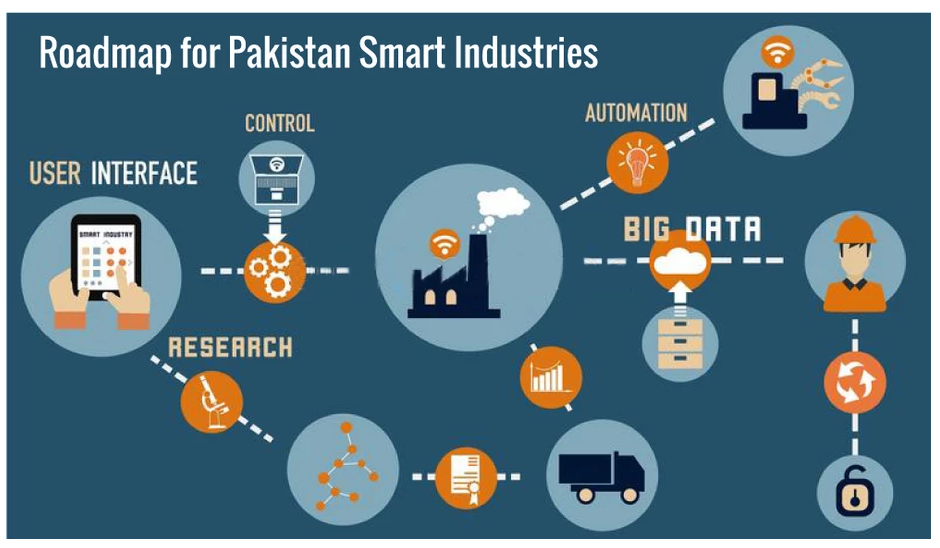

It involves large scale machine to machine communication. Internet of Things such as Sensors, Digital Monitoring devices, Machine & Equipment are integrated to achieve higher automation, better communication, and self monitoring. This point out a smart machine analyzing and diagnosing problems by itself without any manual intervention is required.

Production can be really efficient and personalized according to the customer need. With increase in automation, our time will be free up and we can focus on more complex tasks. We need workforce for building, developing, and implementing such technologies along with ensuing that all this implementation is done in the ethical way.

Components of Industry Revolution 4.0

Following are the components of the Industrial Revolution 4.0

- Cloud Computing

- Big Data Analytics

- Internet of Things

- Artificial Intelligence

- Autonomous Robots

- Cyber Security and System

- System Integration

It emphasizes on digital transformation and increase the value of supply chain management by introducing flexibility, adaptability, and efficiency. It represents the next wave of transformation through technology driving efficiency across operations.

Failing to adopt Revolution 4.0

Failing to adapt the industrial revolution 4.0 will cause organization to fall behind as their processes are no longer competitive.

Benefits of Industry Revolution 4.0

It has several benefits including

- Higher Productivity

- Enable higher efficient decision making

- Optimize integrated process

- Flexibility

- Instant reactions to customers need

- Higher output and lower rejects

After adapting the 4.0 revolution by an organization, there operations will become more efficient. There customer satisfaction will also increase, operation costs reduce, and productivity is higher.

There are still various core skills which human can offer that technology can not handle like Interpersonal skills and creativity. The future job markets will need graduates with open mind that explore the untapped opportunities and only need to embrace more skills like these.