Die casting is a casting process that produces a product with a complex shape by attaching a mold to a die casting machine and rapidly filling the mold with molten alloy at high speed and pressure. Once the mold is created, it can be constantly cast in a cycle of several tens of seconds, making it a mass-production-ready manufacturing technology.

This article will introduce 5 of the best die casting companies in Taiwan, where they specialize in different products.

Introduction to Die Casting

Die casting dates back to 1838, when David Bruce of the United States constructed a manual type casting machine. Because the casting is supposed to have originated approximately 4,000 BC in Mesopotamia, the history of die casting is new. Herman H. Doehler of the United States invented a plunger-type die casting machine in 1905, based on the basis of a type casting machine. This was the world’s first commercial die casting production. In 1907, Joseph Soss of the United States invented a manual horizontal toggle type clamping plunger type hot chamber machine and introduced it to the world for the first time. Doehler started commercial manufacturing of aluminum alloy die-casting in 1915, using the world’s first mobile gooseneck die-casting machine and Josef Polak, a Czech, invented a hydraulic cold chamber die-casting machine with horizontal tightening and vertical injection in 1926. The quality of aluminum alloy die casting has been improved, and the quality of automobile parts and aircraft parts is comparable to that of today. After that, hydraulic horizontal die-casting and horizontal injection die-casting machines appeared, and it has evolved into today’s die-casting.

Die casting is an integral part of today’s manufacturing industry. Without die-casting molds, it is not possible to mass-produce “things” such as automobiles, electric appliances, and daily necessities. There are many types of molds that are used to process and mold materials that are softer than the mold. Glass molds that process glass that become soft by heating at high temperatures to make glass bottles, resin molds that process plastic to make food trays and PET bottles, metal molds that process melted aluminum to make automobile parts, etc.

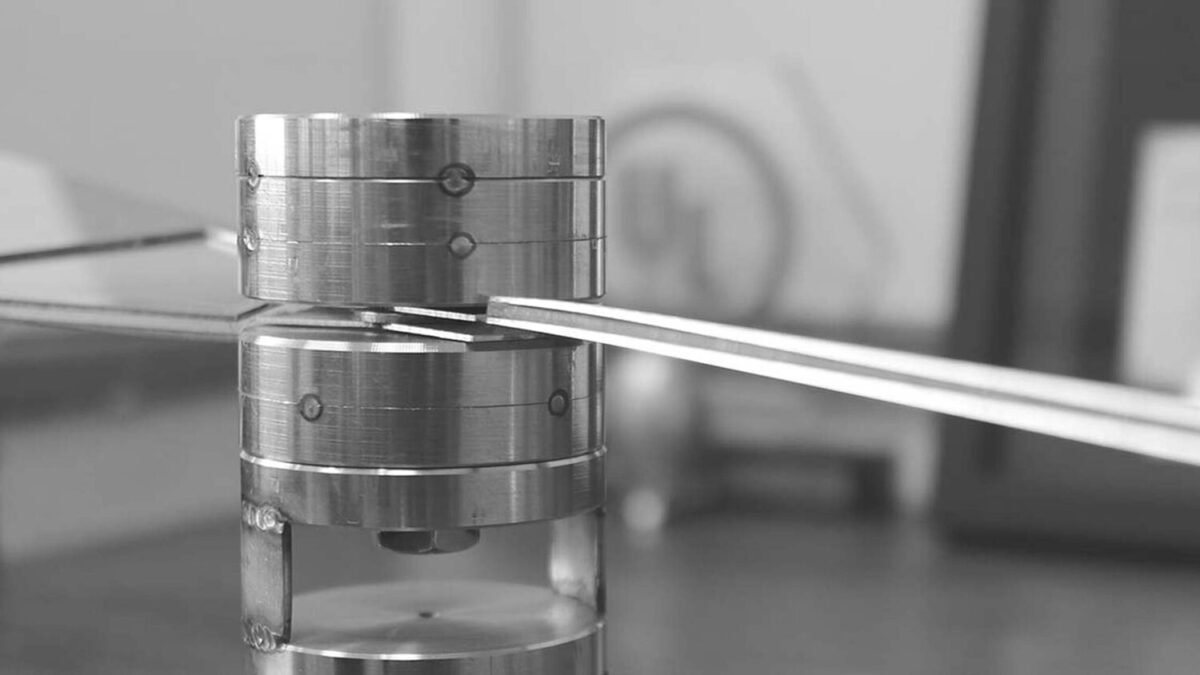

A die-casting mold is a mold for a processing method called the “die-casting method,” which is an advanced casting method for molding metal. The shapes to be molded range from relatively simple shapes such as floral patterns, heart marks, and pipes to three-dimensional intricate shapes for mechanical parts, appliances, and blocks for automobile engines. The materials to be poured into the die casting mold are metals with relatively low melting points such as aluminum, zinc, magnesium, and brass. These metals are heated, completely liquefied, and injected into the mold. The die-casting mold itself is made up of two types; a fixed type and a movable type. Hot water is injected into the gap between these two molds at a high pressure of tens of megapascals. To prevent hot water from spurting out of the gap, the two molds should be pressed together with hundreds of tons of force. When the water has cooled and hardened, the pressure is released and the molded product is removed from the mold.

Top 5 Die Casting Companies in Taiwan

To help you find the best company for your needs, we’ve compiled a list of the top 5 die casting taiwan companies. Each company specializes in a wide range of products and high-quality services. You can learn more about the die-casting manufacturer you want to work with by clicking on their name below.

TEAMSWORLD Customized Die Casting and Plastics Injection Molding Solutions Taiwan

TeamsWorld die casting taiwan, a manufacturing supply chain management company with decades of experience in the lighting industry, is based in Taiwan. It is a certified B-Corporation that seeks solutions to enable sustainable consumption and production in manufacturing that is beneficial. This die casting taiwan company strives to consume resources and products sustainably and responsibly to meet customer’s needs without negatively impacting the environment. By offering integrated consulting solutions for customized metal and plastic parts in the manufacturing sector. They are aiming to establish flexible and robust supply chains in the manufacturing industry. Since 1977, Teamsworld die casting taiwan have provided manufacturing, product development, supply chain management, agile management, and resilient production in lighting, automotive, electronics, subcontracting, metal parts, plastics parts, sustainable management, die casting, and plastic injection. As a die casting taiwan manufacturer, they provide services based on the needs of the customer, such as surface treatments, heat treatments, and mechanical treatments on castings, as well as services ranging from design, mold, product, finish treatment, and assembly.

Peng Ming Enterprise Company

The company has been in operation since 1980. They specialize in Die Casting Mold design and have a strong and talented R&D department. They are located in a well-equipped industrial park. They make die-casting items out of aluminum alloys, zinc alloys, and other metal alloys. The company makes parts for monitor systems, vehicles, and 3C peripherals, among other things. OEM servicing is available for their valued customers. OEM markets, or original equipment manufacturer markets, are generally served by Peng Ming Enterprise Company. These are businesses in which one firm relies on another to manufacture parts for their finished product. So, in their situation, they are the company that manufactures the parts that other companies utilize to create the final products that are sold to customers. Consumers and companies from all over the world contact them to build unique metal components that no other firm can. They can provide you with a high-quality product while keeping it inexpensive by utilizing these materials.

Golden Pond Metal Die Casting Co., Ltd

Jinchi Lai, a pioneer in Taiwan’s die casting industry, created Golden Pond Metal Die Casting Company in 1947. It has been a prominent supplier of custom casting solutions for over 69 years. The majority of the company’s products were gravity sand casting and aluminum die casting parts, as well as bailer, electric fans, motors, and other industrial equipment. Among the items provided are auto components, agricultural machinery parts, electrical parts, motor housing, DIY woodworking machines, and other sectors.

They emphasize casting design reviews with clients prior to mold making to guarantee optimal mold development for each design and increase the quality of aluminum alloy die castings and eliminate any flaws in the future. They also provide a comprehensive range of customized services to the customers, including polishing, grinding, hand grinding, drilling, tapping, and Machined (CNC lathes), milling, and other surface treatment finished and coated.

Ted-Yue Precision Die Casting Co., Ltd

Ted-Yue Precision Die Casting Co., Ltd. was founded in 1983 and specializes in the production of zinc-aluminum alloy die-casting series products. The company has more than 36 years of experience in precision casting technology and mold development. In order to meet the service goal of highest quality and fast delivery of products, they offer complete post-processing automatic CNC technology, various types of perfect electroplating, paint, polishing, grinding, vibration, and other surface treatments, as well as consistent assembly and delivery operations.

Their products are made from simple to complicated designs of zinc-aluminum die-casting parts, such as LED/lighting parts, electrical parts, auto parts and hardware parts, and so on. In addition, they offer design and OEM services. In recent years, the company’s performance has improved remarkably, and it has received ISO 9001: 2015 quality certification and a certificate for its quality management system; and it has developed global business departments to actively explore overseas markets. They always strive to develop die-casting technology in order to optimize revenue for customers.

HF-TI Precision Molding Manufacture Co., Ltd

HF-TI Precision Molding Manufacture Co., Ltd. was founded in 1996 and specializes in Zinc and Aluminum Alloy Die Casting as well as Custom Plastic Injection. Because the foundation of HF-TI is a team of molding technical experts, they are particularly skilled in precision die casting and thinner walls. As a result of its strong mold technology team, HF-TI can be a world-class provider of zinc and aluminum alloy die-casting parts, as well as your finest partner in zinc, aluminum alloy die-casting, and plastic injection molding products. The company’s products include zinc, aluminum alloy die castings, and plastic products of optics, electronics, optical communications, computers, mobile phones, antenna connectors, hardware, etc. Based on more than 10 years of mold development technology and production experience, HF-TI Company has specialized in the production of high-precision die-casting and plastic molds since its start. Furthermore, their introduction of international high-precision measurement instruments, machinery, and equipment to ensure that the quality of the mold meets the needs of customer satisfaction.IGTOK

Conclusion

A customer must consider a number of factors when choosing a die casting company. Considerations include the variety of materials they can work with and their ability to accommodate a wide range of production volumes. You should also look into their pricing structure, as well as how well they interact with customers.

Understanding the die casting field thoroughly will undoubtedly aid customers in locating the best die casting manufacturers capable of finishing the job with ease.