The most common questions we are asked when specifying casters for engine stand ground support applications usually focus on safety factors, shock absorption, corrosion resistance, wheel material and position choices. Parts and supplies were taken to where they needed to be used by cart, then a worker had to carry them to the work table, or leave them on the cart, allowing the user to move on to the next required item. This kart is probably one of the most ergonomically advanced vehicles of all time. This allows objects to be loaded onto it and pushed like a standard cart, then elevated and tilted when needed to create a very ergonomic work environment.

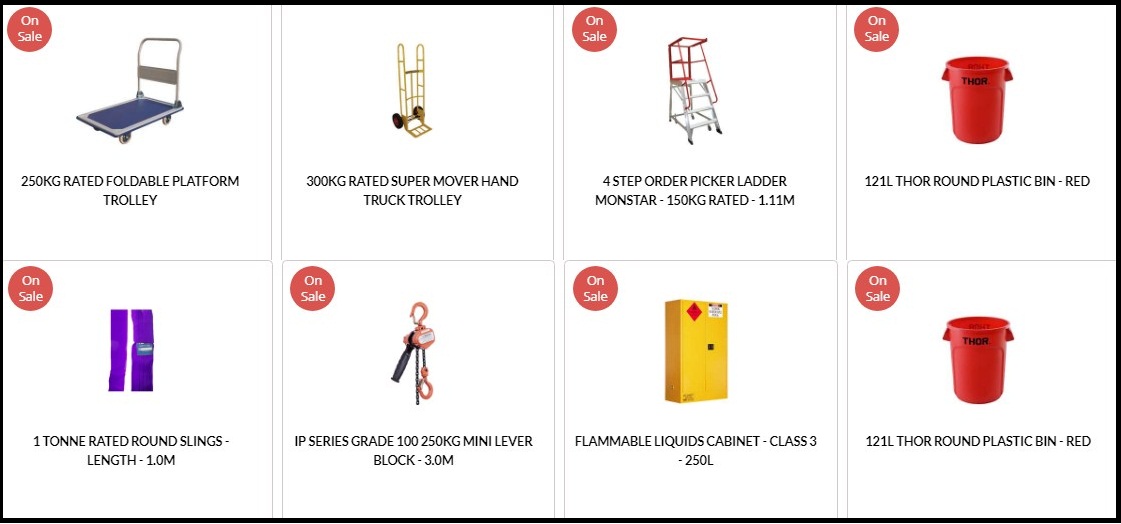

When the jack is removed, the casters can move the jack around. As the jack is driven and the load is applied, the casters deflect and the legs of the jack support the total load. Hopefully, this article helped answer your question and explained what features are typically important for these applications available at www.equip2go.com.au.

Corrosion resistance

Most engines spend most of their time outdoors in the elements, so corrosion protection is more important than a standard caster application. Depending on the degree required by the end user, steps may be taken to zinc plate, then powder coat the coaster rig using stainless steel hardware and other specialty paints and finishes. For extreme applications, aluminium cast rig construction can be used. Aluminium rigs can have an alluding or anodize finish for added corrosion protection.

Tow speed and wheel material

How fast you are pulling the engine stand makes a difference in what type of caster wheel to use. For applications at speeds less than 10 mph, a urethane tread wheel can usually be used. Most catalogue ratings given are for running speeds; please consult an engineer to properly design a urethane wheel for the application. For tow speeds greater than 10 mph, a pneumatic or solid-gas cycle must be used. These wheels can be used at high speeds, although they quickly increase in size to support the equivalent load of a urethane wheel.

End-state features

Sometimes the engine stand needs some specific movement to get it to its final position. These stands can be quite heavy which can make them difficult to move. When this happens, features such as a swivel lock are sometimes used to aid in forward backward movement. A steering tube can also be attached to a swivel caster so that the operator can use a lever to assist the caster to its final position.