In the ever-evolving landscape of industrial innovation, the aspect of material handling has experienced a remarkable transformation with the advent of modern cutting-edge technologies. Among these revolutionary advancements, air compressors, lift decks, and air beams have emerged as total game-changers, propelling material handling equipment into a new era of efficiency and effectiveness. To give you a deeper insight, here we delve into the profound impact of these innovations, exploring how they are reshaping the way industries manage, transport, and manipulate materials.

Air Compressors: Powering Precision and Agility

At its core, an air compressor is a mechanical device that converts power into potential energy stored in compressed air. This compressed air can then be harnessed to perform a myriad of tasks, making it an incredibly versatile tool in the realm of material handling.

One of the key ways in which air compressors are revolutionizing material handling is through the concept of pneumatic systems. Traditionally, material handling equipment relied on labor-intensive processes, conveyor belts, or hydraulics, which often came with limitations in terms of precision, speed, and adaptability. Enter air compressors – they introduce a cleaner, more energy-efficient, and highly precise method of moving materials.

In pneumatic conveying systems, compressed air is utilized to transport bulk materials through pipelines. This method eliminates the need for conventional conveyor belts that are susceptible to wear and tear, and it also minimizes dust and contamination risks, thereby improving product integrity. Industries such as food processing, pharmaceuticals, and mining are benefiting immensely from this innovation, experiencing reduced downtime, increased throughput, and lowered maintenance costs.

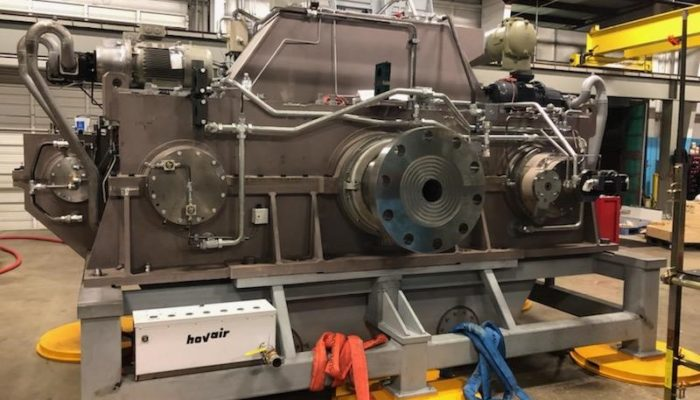

Furthermore, air compressors are instrumental in enhancing the agility and flexibility of material handling operations. With the integration of lift decks, air compressors power platforms that can lift heavy loads with precision. These lift decks offer adaptable elevation solutions, making it possible to position materials at different heights within confined spaces. This versatility is a game-changer in industries like logistics, where optimizing space while maintaining efficiency is paramount.

Lift Decks: Redefining Elevation and Flexibility

Lift decks, a transformative technology powered by air pressure, are revolutionizing the world of industrial material handling equipment, unlocking a new era of efficiency, flexibility, and precision.

Simply put, a lift deck is a versatile platform that utilizes compressed air to elevate heavy loads to various heights, offering a tailored solution to a wide range of material handling challenges. This technology is rapidly reshaping industries by addressing limitations that traditional lifting equipment and methods often encountered.

One of the most significant contributions of lift decks lies in their ability to optimize space utilization. Unlike conventional lifting machinery, lift decks are designed with a compact footprint, making them exceptionally well-suited for operations where space is at a premium. This compactness, coupled with their precise control mechanisms, enables industries to make the most of available space while ensuring efficient material handling processes.

Furthermore, lift decks are redefining flexibility in material handling. With their customizable elevation capabilities, these platforms can be adapted to a diverse array of operational requirements. Whether it’s loading and unloading cargo containers, positioning materials for processing, or supporting assembly line workflows, lift decks offer unmatched adaptability. This flexibility not only streamlines operations but also enhances overall productivity by reducing downtime associated with adjusting traditional lifting equipment.

Lift decks are also instrumental in promoting worker safety. Traditional lifting methods often require manual labor, posing potential risks to employees and leading to fatigue-related inefficiencies. In contrast, lift decks operate under precise and controlled air pressure, minimizing the need for direct human involvement. This results in a safer working environment and reduces the likelihood of workplace injuries, contributing to improved overall operational well-being.

Air Beams: Enabling Effortless Movement

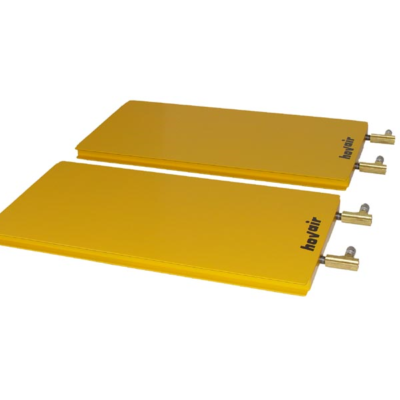

An air beam is a structural element that employs the power of compressed air to create a cushion of air, enabling the seamless movement of heavy loads with minimal friction. This concept is fundamentally altering the way industries approach material handling, unlocking a range of benefits that were previously unattainable through traditional methods.

One of the most remarkable contributions of air beams is their ability to facilitate effortless movement. Older material handling equipment involves the use of conveyor systems, manual pushing, or even complex machinery, all of which introduce friction, wear, and inefficiencies into the process. Air beams, on the other hand, provide a near-frictionless surface upon which heavy loads can glide, allowing for smooth, controlled, and energy-efficient movement. This reduction in friction not only expedites material transfer but also minimizes wear and tear on both the materials being transported and the equipment itself.

The versatility of air beams is another key factor driving their revolutionary impact. These structures can be easily adjusted to accommodate various load sizes and weights, making them suitable for a wide range of applications. Whether it’s moving large manufacturing components along assembly lines or transporting delicate materials in pharmaceutical production, air beams offer a customizable and adaptable solution that enhances efficiency across diverse industries.

Another point worth noting is that air beams contribute to improved safety and reduced operational complexity. Traditional material handling methods often require manual labor, posing risks to workers and potentially compromising product integrity. Air beams alleviate the need for excessive force during movement, reducing the likelihood of accidents and injuries. This safety enhancement, coupled with the simplicity of air beam operation, streamlines workflows and minimizes the learning curve for operators.

Modern Material Handling Equipment – Final Thoughts

It is safe to say that the industrial landscape is undergoing a profound transformation, driven by the development of innovative technologies such as air compressors, lift decks, and air beams. These advancements have elevated the way industries manage, transport, and manipulate materials, bringing about an era of enhanced precision, agility, and efficiency.

Integrating these groundbreaking solutions into their operations, has become vital for industries in all sectors. If you happen to be on the hunt for reliable, reputable and durable material handling equipment, we highly recommend Hovair Systems – a brand name known for its innovation. With a unique grasp on modern technology, the company offers products possessing ultimate efficiency. Contact them today to set your industry up for success.

Author Bio

Arthur D. is an accomplished industrial engineer and thought leader with a passion for optimizing material handling processes. With over a decade of experience in the field, Arthur has developed a deep understanding of the intricacies involved in modern warehouse operations and supply chain management. He hopes to guide others and help them adopt material handling strategies for a more productive and sustainable future.