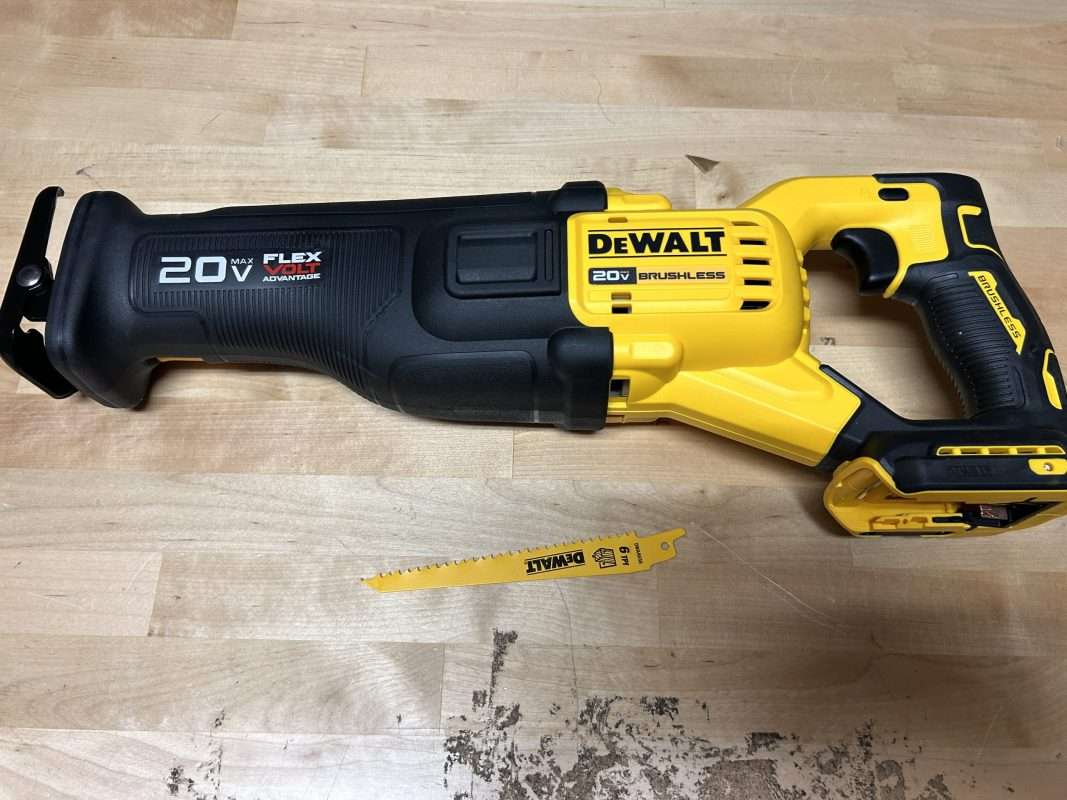

Mastering Efficiency: Best Practices for Optimizing Dewalt Cordless Saws

Introduction:

Dewalt cordless saws have become indispensable tools in the arsenal of both professionals and DIY enthusiasts. These versatile tools offer convenience, portability, and power, allowing users to accomplish a wide array of cutting tasks with precision and ease. However, to maximize their potential and ensure optimal performance, employing the best practices is crucial. In this blog, we’ll delve into effective tips and techniques for harnessing the full potential of Dewalt cordless saws across diverse applications.

Selecting the Right Blade:

The choice of blade significantly impacts the saw’s performance. Different materia ls demand specific blade types for efficient cutting. Dewalt cordless saws support various blade options designed for wood, metal, plastic, and other materials. Using the appropriate blade not only enhances cutting precision but also prolongs the saw’s lifespan by reducing wear and tear.

ls demand specific blade types for efficient cutting. Dewalt cordless saws support various blade options designed for wood, metal, plastic, and other materials. Using the appropriate blade not only enhances cutting precision but also prolongs the saw’s lifespan by reducing wear and tear.

Battery Management:

Optimal battery usage is key to uninterrupted workflow. Investing in high-quality lithium-ion batteries and keeping them fully charged before commencing work ensures consistent power delivery. Moreover, carrying spare batteries can prevent workflow disruptions, especially for extensive projects, enabling seamless transitions and continuous operation.

Maintaining Blade Sharpness:

A dull blade not only compromises cutting quality but also strains the motor, impacting the saw’s overall performance. Regularly inspect and sharpen the blade to retain its sharpness. Additionally, keeping the blade clean from debris and residue prevents friction, allowing smoother cuts and prolonging the blade’s longevity.

Adjusting Speed and Depth:

Adjusting the saw’s speed and depth settings according to the material being cut is crucial. Higher speeds may be suitable for softer materials, while slower speeds offer better control and precision for denser substances. Similarly, adjusting the cutting depth prevents overexertion of the saw and ensures accurate and efficient cuts.

Utilizing Safety Measures:

Prioritizing safety is non-negotiable when using power tools. Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection. Additionally, familiarize yourself with the saw’s safety features and use them diligently to minimize the risk of accidents.

Techniques for Various Applications:

- Precision Cutting: Utilize guides and clamps for accurate and straight cuts, especially for woodworking projects.

- Bevel Cuts: Master the art of bevel cutting by adjusting the saw’s angle settings for versatile applications such as creating angled edges or joints.

- Rip Cuts: Employ rip-cutting techniques for cutting along the length of the material, optimizing efficiency for larger pieces.

- Cross-Cuts: Use appropriate jigs or miter gauges for perpendicular or angled cross-cuts, ensuring accuracy and consistency.

Regular Maintenance:

Routine maintenance is vital to keep Dewalt cordless saws in optimal condition. Clean the saw after each use, inspect for any damages or wear, and lubricate moving parts as per the manufacturer’s guidelines. Regular maintenance not only ensures longevity but also enhances the saw’s performance and reliability.

Conclusion:

Mastering the art of utilizing Dewalt cordless saws involves a combination of selecting the right accessories, understanding various cutting techniques, maintaining the tool diligently, and prioritizing safety. By implementing these best practices, users can unlock the full potential of these powerful tools across diverse applications, ensuring efficiency, precision, and longevity.