If you want to maximise the efficiency and performance of your compensation chuck machine, this article is for you. We’ll delve into the key components that make up this essential piece of equipment, explain how it functions, and provide best practises for maintenance and cleaning.

Get ready to optimise your operations and achieve impressive results with your compensation chuck machine.

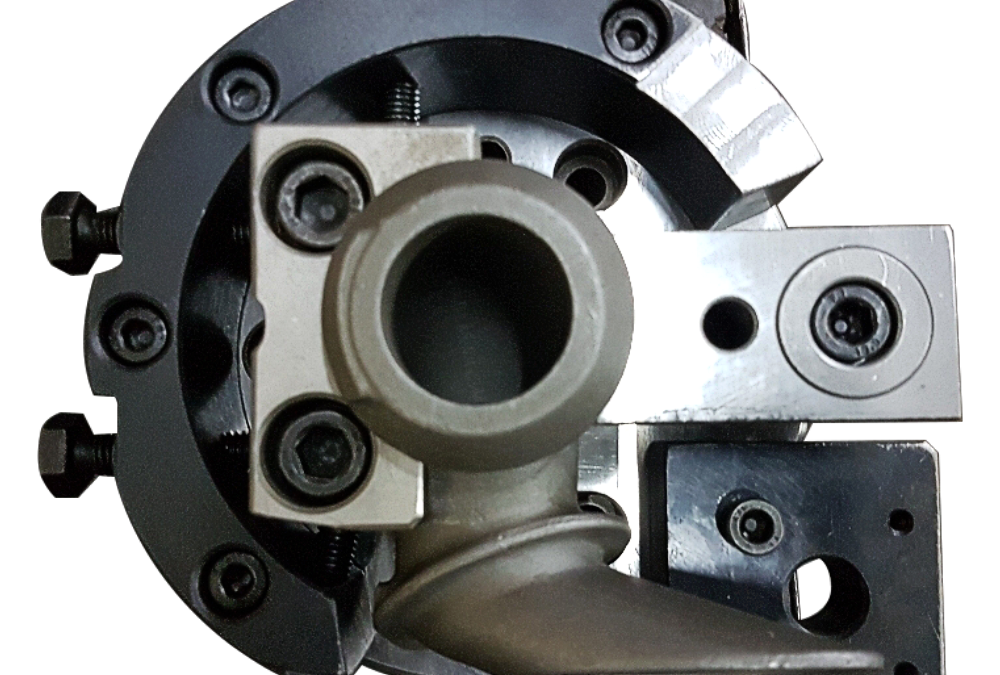

Understanding the Functionality of Your Compensation Chuck Machine

Understanding how the functionality of your compensation chuck machine works is essential for maximum efficiency. To improve efficiency, it is crucial to identify and troubleshoot common issues that may arise during operation.

One common issue is misalignment between the chuck and the workpiece, which can result in inaccurate compensation. To troubleshoot this, ensure that the chuck is properly aligned with the workpiece by using alignment tools and techniques.

Another issue could be excessive vibration, leading to poor compensation performance. To address this, check for any loose components or worn-out parts that may cause vibrations and replace them if necessary.

Best Practises for Maintaining and Cleaning Your Compensation Chuck Machine

Regularly cleaning and lubricating your manual indexing chuck can help prevent friction-related issues and keep it operating efficiently. Proper lubrication techniques for your compensation chuck machine are essential to ensuring optimal performance.

Start by selecting the appropriate lubricant based on the manufacturer’s recommendations. Apply a thin layer of lubricant to all moving parts, paying close attention to the chuck jaws, slides, and spindle bearings. Avoid over-lubrication, as it may attract dust and debris, leading to potential damage.

Additionally, regularly inspecting your machine for common issues can help troubleshoot any problems before they escalate.

Advanced Techniques to Maximise the Performance of Your Compensation Chuck Machine

Using advanced techniques can greatly enhance the performance of your chuck machine. When it comes to compensation chuck machines, troubleshooting is crucial for optimal functionality. One innovative feature of compensation chuck machines is the ability to automatically adjust the compensation pressure based on real-time data. This ensures precise and consistent chucking force, resulting in improved accuracy and reduced scrap rates.

Additionally, advanced compensation chuck machines are equipped with integrated sensors that monitor various parameters, such as temperature and vibration. These sensors provide valuable insights into the machine’s health and allow for proactive maintenance, minimising downtime and increasing overall productivity.

Conclusion

Optimising your compensation chuck machine requires a thorough understanding of its key components and functionality. By following best practises for maintenance and cleaning, you can ensure its longevity and efficient performance.

Remember to regularly monitor and analyse the data to identify any areas for improvement. By adopting an analytical approach, you can maximise the potential of your compensation chuck machine and achieve optimal results in your manufacturing processes.

Website: https://www.vishalmachinetools.com/