In the world of industrial manufacturing, efficiency is key. Every process needs to be as efficient as possible to reduce costs, speed up production, and maximize profits. One way to do this is by using conveyor rollers for your manufacturing process. Conveyor rollers are a simple yet effective tool that can help keep your operations running smoothly and with minimal disruption. Let’s take a look at how conveyor rollers can help you maximize efficiency in your operation.

What are Conveyor Rollers?

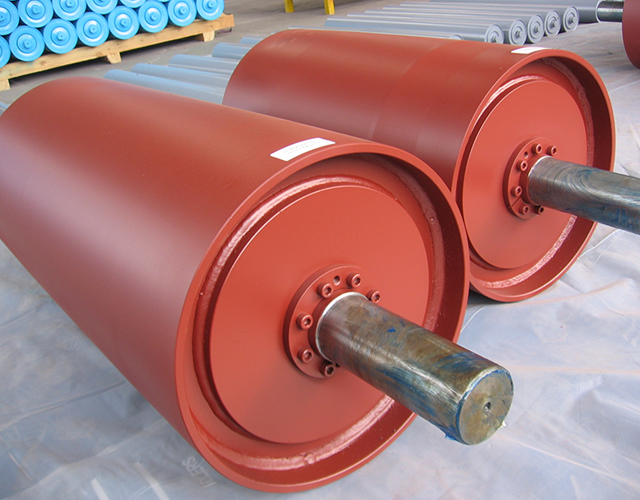

Industrial conveyor rollers are cylindrical tubes that move materials along an assembly line or other production process. They come in various shapes, sizes, and materials depending on the type of product you’re moving and the environment you’re working in. The most common type of roller is the steel or aluminum roller which is durable enough to withstand tough operating conditions but lightweight enough for easy installation and maintenance.

Benefits of Using Conveyor Rollers

Using conveyor rollers helps increase productivity by decreasing the amount of manual labor needed to transport goods from one station to another. This reduces labor costs while also increasing safety since there is less risk of injury due to manual handling of heavy items. Furthermore, they provide a smooth transition across different surfaces like inclined surfaces or tight turns which eliminates additional costs associated with having multiple machines or manpower required for those tasks. Additionally, they require no lubrication which means less downtime due to maintenance requirements and longer system life spans due to reduced wear-and-tear on components.

How Can I Use Conveyor Rollers?

Industrial conveyor rollers can be used in a wide range of applications from material handling systems like assembly lines to packaging systems like shrink wrap machines and more. They can even be used for transportation purposes such as moving pallets between warehouses or shipping docks or transporting bulk goods from one location to another efficiently without having manual labor involved. No matter what type of application you have, conveyor rollers can help optimize your operations by reducing downtime, improving safety standards, and increasing overall efficiency within your facility!

Choose Us for Quality Conveyor Rollers

At us, we’re proud to be conveyor roller manufacturers that provide a wide selection of conveyor rollers that are designed and tested for quality assurance. Our products are durable enough to withstand harsh environmental conditions while also being lightweight and easy to install. We offer several customization options so you can find exactly what you need.

Conclusion:

Whether you are looking for a cost-effective solution for your industrial operations or simply want an easier way to move heavy items around your facility safely and efficiently, conveyor rollers are definitely worth considering! Investing in quality conveyor rollers will not only improve your operations but will also save money in the long run due to fewer repairs or replacements needed down the line. Take the time now to research different types of conveyors available so that you can make an informed decision when it comes time to invest in them – it’ll pay off later!