To maximize the efficiency of these tools, they need to be upgraded with a stationary power chuck or compensation chuck. This article will explore how such upgrades can help companies increase their overall production efficiency and save costs in the long run.

Power Chuck Upgrades

Power Chuck Upgrades are essential for maximizing efficiency in industrial applications. With the proper upgrades, a compensation chuck can help to provide smoother operation at higher speeds and more precision for more significant parts.

Advantages of Upgrading Power Chuck

The first advantage of upgrading is increased speed and accuracy. Modernized power chucks with newer parts allow more torque to be applied when tightening, ensuring faster run times and higher precision when machining. This also helps reduce downtime due to mechanical issues and wear and tear on older parts, which could impede productivity. Additionally, newer power chucks often have improved cooling systems that keep them running at optimal temperatures even during heavy workloads to ensure consistent results with each use.

Types of Power Chucks

The first type is the standard collet chuck, operated by two levers and offers versatile clamping capabilities. This type of chuck is suitable for small parts with simple geometries and can be used in various settings, such as machine shops, production lines, and automated assembly operations.

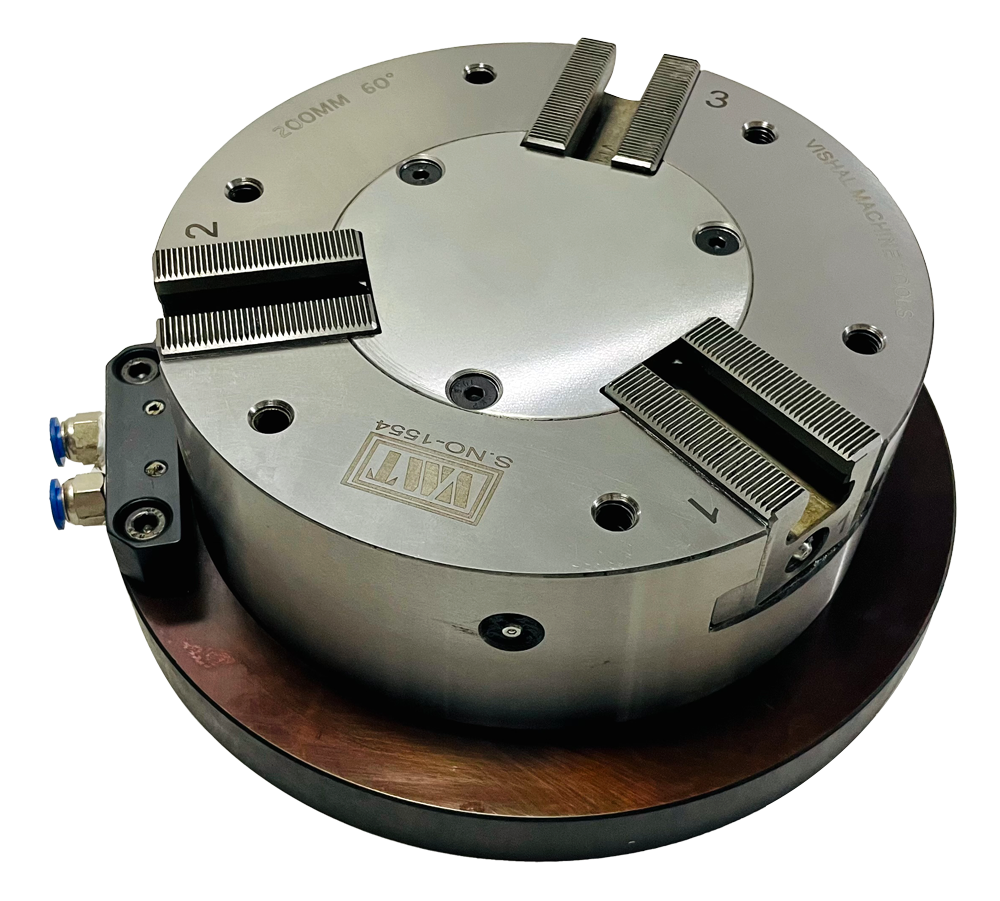

The next type of power chuck is the three-jaw chuck which has three adjustable jaws that can grip objects with more complex shapes or sizes than those handled by standard two-jaw chucks.

Benefits of Higher Efficiency

The most obvious benefit of higher efficiency with power chuck upgrades is increased productivity. By making workpieces secure during machining, operators can quickly reduce setup time and move from job to job. This decreases the overall production cycle time and allows more jobs to be completed in less time, lowering labor costs and downtime.

Cost Considerations

Cost considerations should always be considered when maximizing efficiency with power chuck upgrades. Many industrial-scale machining operations require a significant upfront expense for equipment and materials. For example, lathes and grinders can range in price from hundreds to thousands of dollars, depending on size and quality. Additionally, high-quality power chucks can also be costly but are essential for ensuring optimal performance of the machine tools.

Conclusion

By investing in a quality power chuck upgrade, businesses of all sizes can reap the rewards for many years. With the right upgrades, companies can increase speed, reduce costs, and improve product quality – allowing them to complete projects with the confidence that they’re efficiently creating precision products. Additionally, by investing in upgrades such as increased air pressure or hydraulic clamping systems, users get more out of their machinery while minimizing errors that could lead to costly machine downtime.

website: https://vishalmachinetools.com/