Plastic profile extrusion is a process that has been around for several years and is widely used in various industries, such as construction, automotive, and medical equipment. It involves the production of plastic extrusion products through the melting of raw plastic materials and the shaping of the melted plastic into a continuous profile.

Choosing plastic profile extrusion companies for your manufacturing needs has several advantages, and in this article, we will discuss some of them.

Cost-Effective

One of the main advantages of plastic profile extrusion companies is that they offer cost-effective solutions for manufacturing plastic extrusion products. Plastic extrusion is a highly automated process that allows for the production of large volumes of plastic products in a short amount of time, which reduces labor costs. Additionally, plastic profile extrusion companies can purchase raw materials in bulk, which lowers material costs.

Furthermore, plastic profile extrusion companies use specialized equipment and technologies to produce high-quality plastic extrusion products efficiently. This ensures that the products meet the required specifications while keeping the manufacturing costs low.

Versatility

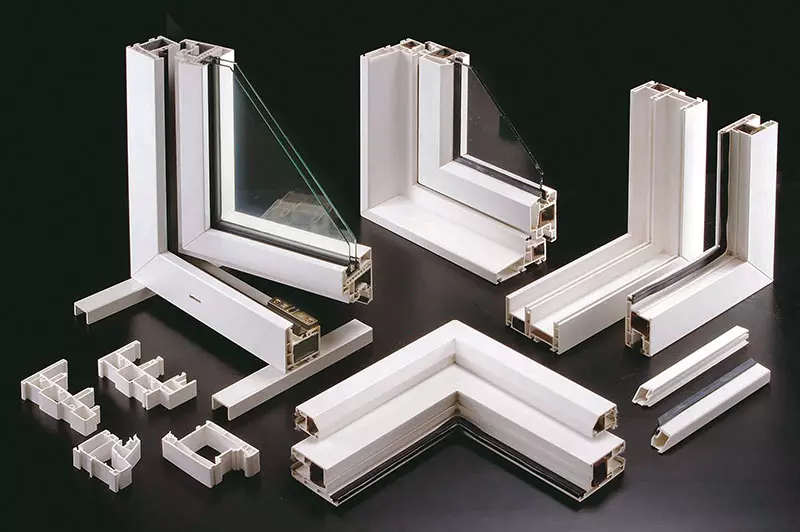

Plastic profile extrusion companies offer a wide range of plastic extrusion products, which can be customized to suit the specific requirements of their customers. These products can be made in different shapes, sizes, and colors, and can be used in various industries, including construction, automotive, and medical equipment.

Additionally, plastic extrusion products can be made from different types of plastics, such as PVC, ABS, PE, and PP, which have different properties and can be used for different applications. This versatility makes plastic profile extrusion companies an ideal choice for businesses that require custom-made plastic products.

Consistency

Plastic profile extrusion companies use advanced technologies and equipment to produce high-quality plastic extrusion products that are consistent in shape, size, and quality. This ensures that the products meet the required specifications and can be used for their intended purpose.

Furthermore, plastic profile extrusion companies have quality control processes in place to ensure that the products meet the required standards. This includes testing the products for strength, durability, and chemical resistance, among other properties.

Durability

Plastic extrusion products produced by plastic profile extrusion companies are durable and can withstand harsh environmental conditions. This is because plastic extrusion products are made from high-quality plastics that have excellent resistance to heat, chemicals, and UV radiation.

Additionally, plastic profile extrusion companies use specialized techniques to produce plastic extrusion products that are strong and resistant to wear and tear. This makes plastic extrusion products an ideal choice for applications that require long-lasting and durable products.

Customization

Plastic profile extrusion companies offer customization services that allow their customers to design plastic extrusion products that meet their specific requirements. This includes designing products in different shapes, sizes, and colors, and incorporating features such as holes, grooves, and flanges, among others.

Additionally, plastic profile extrusion companies have a team of experts who can help their customers design plastic extrusion products that are functional and aesthetically pleasing. This ensures that the products meet the customers’ requirements while also meeting the required standards.

Speed of Production

Plastic profile extrusion companies use advanced technologies and equipment to produce plastic extrusion products quickly and efficiently. This ensures that the products are produced in a short amount of time, which can be crucial in industries where time is of the essence.

Furthermore, plastic profile extrusion companies have the capability to produce large volumes of plastic extrusion products in a short amount of time, which can be beneficial for businesses that require large quantities of plastic products.

Environmental Sustainability

Plastic profile extrusion companies are committed to environmental sustainability and use environmentally friendly materials and processes to produce plastic extrusion products. This includes using recycled materials, which reduces waste and conserves natural resources.