Directional control valves are an essential component of many hydraulic systems. They play a crucial role in controlling the flow of hydraulic fluid, which is necessary to move various hydraulic components. Understanding the functionality, and applications of directional control valves is crucial to ensure the proper functioning of hydraulic systems. In this article, we will discuss everything you need to know about directional control valves.

What is a Directional Control Valve?

A directional control valve is a hydraulic component that is used to control the flow of hydraulic fluid in a hydraulic system. The valve directs fluid flow to the hydraulic actuators, such as hydraulic cylinders and motors, and controls the direction of movement of these actuators. Directional control valves are crucial components in hydraulic systems as they control the movement of various hydraulic components, such as cylinders and motors, which perform the necessary work.

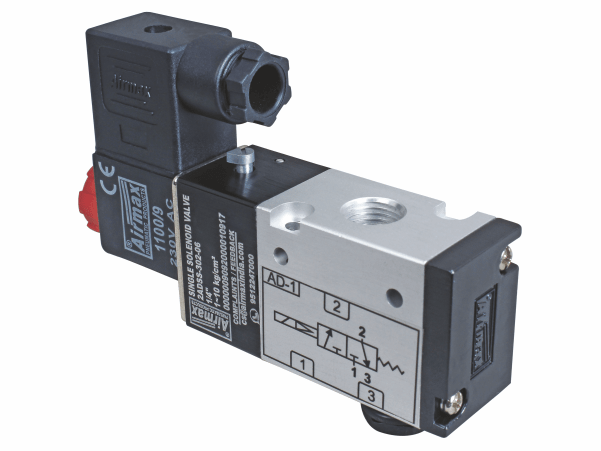

The directional control valve consists of a valve body, a spool, and actuating mechanisms. The valve body houses the spool and actuating mechanisms and is connected to the hydraulic system. The spool moves within the valve body, and its position determines the direction of fluid flow. The actuating mechanisms, such as solenoids or levers, control the movement of the spool.

Applications of Directional Control Valves

Directional control valves are used in a wide range of hydraulic systems. Some common applications of directional control valves include:

Mobile equipment: Directional control valves are used in mobile equipment such as excavators, bulldozers, and cranes to control the movement of hydraulic cylinders.

Industrial equipment: Directional control valves are used in industrial equipment such as hydraulic presses, machine tools, and plastic injection molding machines to control the movement of hydraulic cylinders.

Agricultural equipment: Directional control valves are used in agricultural equipment such as tractors and harvesters to control the movement of hydraulic cylinders and motors.

Aerospace and aviation: Directional control valves are used in aerospace and aviation industries in hydraulic systems that control the movement of flaps, landing gear, and other components.

Marine industry: Directional control valves are used in the marine industry in hydraulic systems that control the movement of steering mechanisms, winches, and other components.

Oil and gas industry: Directional control valves are used in hydraulic systems in the oil and gas industry to control the movement of drilling equipment and other hydraulic components.

Choosing the Right Directional Control Valve for Your Application

Choosing the right directional control valve for your application is crucial to ensure the proper functioning of your hydraulic system. Here are some factors to consider when selecting a directional control valve:

Type of valve: Choose the type of valve that is appropriate for your application. Consider factors such as the number of ports and positions required, the flow rate and pressure of the hydraulic system, and the environment in which the valve will be used.

Flow rate and pressure: Consider the flow rate and pressure of the hydraulic system when selecting a directional control valve. Choose a valve that can handle the flow rate and pressure of your system.

Mounting options: Consider the mounting options available for the valve. Choose a valve that can be mounted in the desired location in your hydraulic system.

Actuation method: Consider the actuation method of the valve. Choose a valve that can be actuated using the appropriate method for your application, such as a solenoid or manual lever.

Material and environment: Consider the materials used in the valve and the environment in which it will be used. Choose a valve made of materials that can withstand the operating conditions of your hydraulic system, such as temperature and pressure fluctuations and exposure to corrosive or abrasive materials.

In conclusion, directional control valves are essential components of hydraulic systems, and understanding their functionality, and applications is crucial to ensure the proper functioning of hydraulic systems. When selecting a directional control valve for your application, consider factors such as the type of valve, flow rate and pressure, mounting options, actuation method, and materials used in the valve. By choosing the right directional control valve, you can ensure the optimal performance of your hydraulic system.