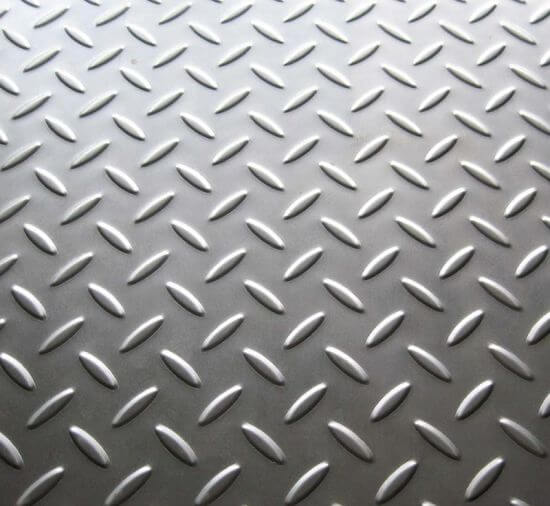

Nearly every competent tradesperson has dealt with different forms of sheet metal in some capacity, and it is employed for both structural and aesthetic purposes. Here are a few of the most typical applications for sheet metal offered by the checkered sheets supplier.

How Does Sheet Metal Work?

The broad group of metals with a thickness between 0.018 and 0.250 is known as sheet metal. Instead of using inches or millimetres to measure sheet metal thickness, gauges are frequently used instead.

To indicate their thicknesses, various types of material will use somewhat different gauge systems. Sheet metal may be made from a wide range of materials, including copper, brass, aluminium, steel, galvanised steel, and stainless steel.

What Is the Purpose of Sheet Metal?

Depending on the type of metal being used, sheet metal has a variety of functions. Only some applications will be able to use certain types of sheet metal to fulfil performance requirements. What a sheet of metal is used for is frequently determined by the type of material:

Used For Fabrication

When corrosion is not an issue or if a coating procedure will be utilised to protect the steel from the environment after fabrication, carbon steel sheet is frequently used for general manufacturing. It may be utilized for anything, including business signage and automobile bodywork. Its flexibility is a result of its affordability and generally higher tensile strength when compared to copper and aluminium.

Used In Automotive Parts

A type of carbon steel sheet known as galvanised steel sheet has undergone the galvanising process, which coats the steel’s outside with zinc oxide to prevent corrosion. Galvanized steel is widely used in automobile components and items that come into contact with water, such as buckets, irrigation tubing, maritime vessels and greenhouse equipment.

Used In Engine Component

Because it contains more alloying elements than galvanised or carbon steel, stainless steel sheets often cost more. However, the alloying components improve the corrosion resistance of stainless steel sheets.

Because of its capacity to resist corrosion, it is frequently used in important applications such as food handling equipment, pharmaceutical processing machinery, high-performance maritime constructions, and aircraft engine components.Additionally, stainless steel sheet has a pleasing visual quality that makes them attractive for appliances and signs.

Used In Construction

Due to its density, which is around one-third that of steel, the aluminium sheet is commonly employed in situations where weight is an issue. Additionally, it has good corrosion resistance. The aluminium sheet is a fantastic material for boat parts, maritime constructions, cookware, automotive, and aerospace components because of its lightweight and resistance to corrosion.

Used In Machinery

Electrical conductivity, aesthetic attractiveness, and malleability are all qualities of copper sheets. It is employed in machinery where it is necessary to deliver energy to a workpiece quickly, such as in some resistance welding machinery or some battery systems. It is frequently used in artwork and home design due to its malleability and great aesthetic features.

Usefulness Of Sheet Metal

Numerous advantages arise with sheet metal offered by the checkered sheets supplier. The first is how simple it is to move this stuff. Because it is thin and lightweight, sheet metal is easily stacked. In light of this, shipping even in huge quantities is not a challenge.