In the world of modern engineering and electronics, cables play an indispensable role in connecting various components and ensuring the smooth operation of countless devices. However, the term “cable harness assembly” might not be familiar to everyone. In this comprehensive guide, we delve deep into the intricacies of cable harness assemblies, shedding light on their importance, components, manufacturing processes, and applications. So, let’s embark on this journey to unravel the world of cable harness assemblies.

Understanding Cable Harness Assemblies

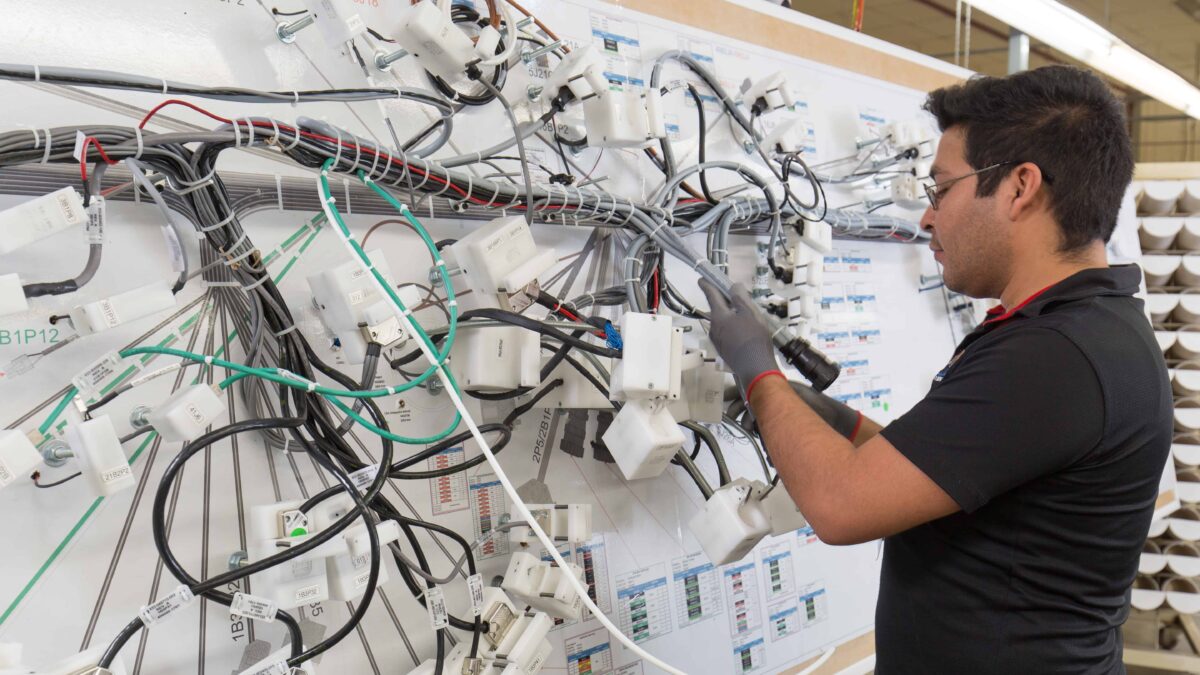

A cable harness assembly, also known as a wire harness or wiring loom, is a meticulously organized bundle of wires or cables that are used to transmit signals or electrical power. These assemblies are designed to optimize the efficiency and safety of electronic systems by keeping wires neatly organized and protected from environmental factors.

The Key Components

1. Wires and Cables

At the heart of any cable harness assembly are the wires and cables. These components serve as the conduits for electrical signals and power transmission. High-quality wires and cables are essential for ensuring the longevity and reliability of the assembly.

2. Connectors

Connectors are the bridge between different components of the assembly. They allow for the seamless attachment and detachment of various devices or components, making maintenance and repairs easier.

3. Terminals

Terminals are crucial for connecting wires to other devices or components. They come in various forms, including crimped, soldered, or insulation displacement terminals, depending on the specific application.

4. Protective Sleeves

To safeguard the wires from abrasion, heat, moisture, and other potential hazards, protective sleeves or tubing are used. These sleeves come in various materials, including PVC, polyethylene, and heat-shrinkable tubing.

The Manufacturing Process

1. Design and Planning

The process of creating a cable harness assembly begins with meticulous design and planning. Engineers analyze the specific requirements of the system, taking into consideration factors such as the number of wires, length, and the types of connectors needed.

2. Wire Cutting and Stripping

High-precision machines are used to cut and strip wires to the required lengths. This step ensures uniformity and accuracy in the assembly.

3. Crimping and Termination

Connectors and terminals are attached to the wires through crimping or soldering. This step demands precision to guarantee a reliable electrical connection.

4. Bundling and Taping

After individual wires are prepared, they are bundled together, and harness tape is used to keep them in place. The tape provides protection and ensures that the assembly remains tidy and organized.

5. Quality Control

Before the final product is shipped, rigorous quality control measures are implemented. This includes electrical testing, visual inspections, and verifying that the assembly meets all specifications.

Applications of Cable Harness Assemblies

Cable harness assemblies find applications across a wide range of industries, including:

1. Automotive

In the automotive industry Anzer, cable harness assemblies are used for connecting various components, such as the engine, sensors, lights, and the entertainment system. These assemblies ensure reliable communication and power distribution within the vehicle.

2. Aerospace

Aerospace systems rely heavily on cable harness assemblies for their intricate electrical systems. They are essential for communication, navigation, and control in aircraft and spacecraft.

3. Electronics

From consumer electronics to industrial machinery, cable harness assemblies are used extensively. They enable the efficient transmission of signals and power in everything from smartphones to manufacturing equipment.

4. Medical Devices

Medical devices require precision and reliability. Cable harness assemblies play a critical role in ensuring the proper functioning of diagnostic and treatment equipment.

The Bottom Line

In the world of engineering and electronics, cable harness assemblies are the unsung heroes that enable the seamless functioning of countless devices and systems. Understanding the importance of these assemblies, their components, and the meticulous manufacturing process is crucial for anyone in the field. Whether you’re an engineer, a technician, or simply someone curious about the inner workings of modern technology, the knowledge of cable harness assemblies is a valuable asset.

So, the next time you use your smartphone, drive your car, or fly in an airplane, remember that behind the scenes, cable harness assemblies are quietly doing their job, ensuring that the world keeps moving forward technologically and efficiently.