What Is PVC Resin Used For?

Regardless of what you’re using PVC resin for, there’s a lot to know about this type of material. Here are a few things to think about

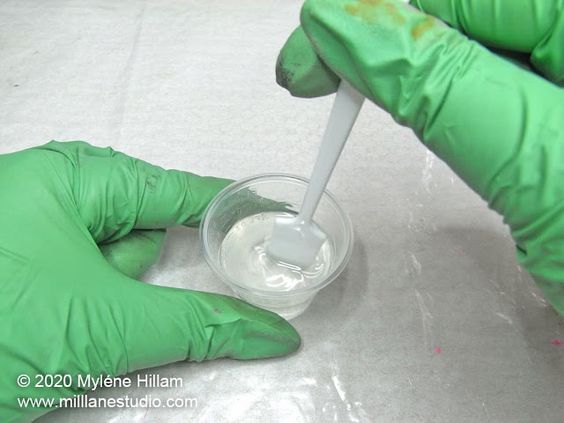

Paste grade

Compared to conventional materials, PVC paste resin is lighter in weight and less expensive. Its performance is also much better and easy to install. Its chemical stability is also good. It is suitable for various uses, including spray coating, plastisol, foaming, and rotational forming.

Besides, the demand for PVC paste resin is increasing due to increasing construction activities in developing countries. These countries are looking for materials to reduce the weight and thickness of their products. In addition, the government of these countries are taking initiatives to encourage the use of electric vehicles. These vehicles have higher energy efficiency and lower weight. This is expected to drive the growth of the global PVC Paste Resin market during the forecast period.

Asia Pacific is expected to have a large share of the global PVC paste resin market during its forecast period. This region includes countries such as India, China, Indonesia, and Malaysia.

Source:https://i.pinimg.com

Bulk

Often called polyvinyl chloride or PVC, this is the third most widely used synthetic polymer of plastic. It is used to produce wall paper, flooring, and artificial leather. PVC resin is also used in manufacturing cables and fittings.

PVC is manufactured in powder form or pellets, which can then be processed through extrusion, calendering, or injection molding. The resin is usually manufactured through the emulsion polymerization process. It is also available in suspension form.

Bulk PVC is used for hard sheets, bottles, and fittings. In recent years, suspension resin technology has edged out bulk PVC. It is used to produce tough coatings for conveyor belts. PVC is not only resistant to weathering and chemical rotting, but it is also a strong flame inhibitor. It is the preferred material for many long-life outdoor products.

Plasticizers

Typically, plasticizers are used for conversion of rigid PVC to softer material. Their function is to widen the distance between the PVC polymer molecules. Plasticizers are typically colorless liquids. They are added to PVC blends in large amounts.

The most commonly used plasticizers are phthalates. They are low cost and have excellent plasticizing properties. However, they are banned in toys and baby-feeding products.

To improve the plasticization properties of zhongtai pvc, researchers have sought to develop branched polymeric plasticizers. The results show that plasticizers with high branching exhibit poor plasticization properties. They are also found to entangle with the PVC backbone. This results in decreased mobility.

In the current study, polymer cardanol-based polyoxyethylene ether carboxylates (CPEC) were synthesized by ethoxylation of cardanol. The molecular weights of these CPECs were relatively high.

Source:https://i.pinimg.com

Recyclability

Whether you are looking to recycle your PVC resin, or are looking to increase the lifespan of a current PVC product, there are a number of options. However, determining what the best option is for your situation isn’t always easy.

PVC materials are typically difficult to separate. They contain a range of additives, and the composition of the material may vary considerably. Therefore, it is important to ensure that your waste is collected safely and in a manner that will reduce the risk of release of chemicals.

There are several different thermal recycling processes available for PVC waste. The Solvay process is one such example, using dry scrubbers with sodium bicarbonate.

Mechanical recycling is a more conventional method for recycling PVC. It involves grinding up the waste into granules, and then processing them into other products. This method is less expensive than chemical recycling, which requires elaborate facilities.

Impacts on the environment

Several types of highly toxic chemicals are generated during zhongtai chemical pvc resin production. These chemicals are capable of causing severe health effects and neurological damage. They can also cause cancer, endocrine disruption and endometriosis.

As a result, the PVC industry has been under intense pressure from a number of industry players to reduce its environmental footprint. The formal government has also made a number of changes to PVC legislation.

The PVC industry has responded to this pressure by re-designing its production process. It has decreased the energy input required to produce a ton of PVC by 9.5%, from the baseline period of 2007-2008.

The PVC industry has also taken leadership in addressing the environmental impacts of its production. In the past two decades, it has been acknowledged for its leadership in environmental awareness, product innovation and recycling.