In the realm of manufacturing, efficiency and cost-effectiveness are two pillars that every industry strives to uphold. Whether you’re producing bolts, screws, or any threaded components, achieving high-quality results while keeping costs down is essential for maintaining competitiveness in today’s market. One tool that plays a crucial role in this endeavor is the flat thread rolling die. In this article, we’ll explore why incorporating flat thread rolling dies into your manufacturing process can significantly boost efficiency and reduce costs.

Understanding Thread Rolling

Before diving into the benefits of flat thread rolling dies, let’s briefly review what thread rolling entails. Thread rolling is a cold-forming process where a hardened steel die is used to form threads on a workpiece. Unlike traditional cutting methods like threading, which remove material to create threads, thread rolling displaces material to form the threads, resulting in increased strength and improved surface finish.

The Importance of Flat Thread Rolling Dies

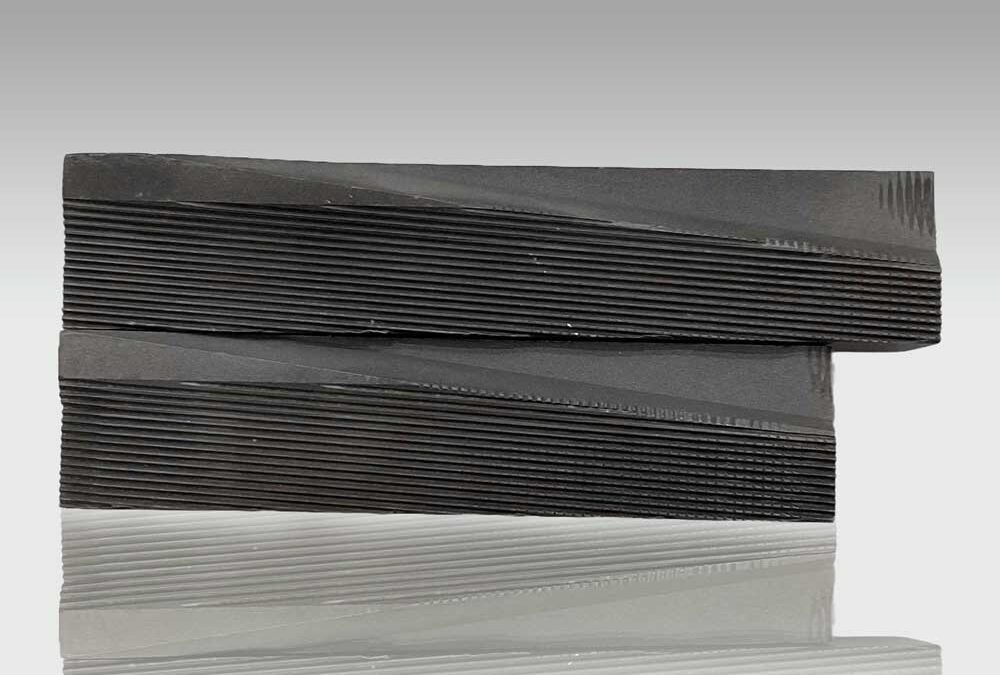

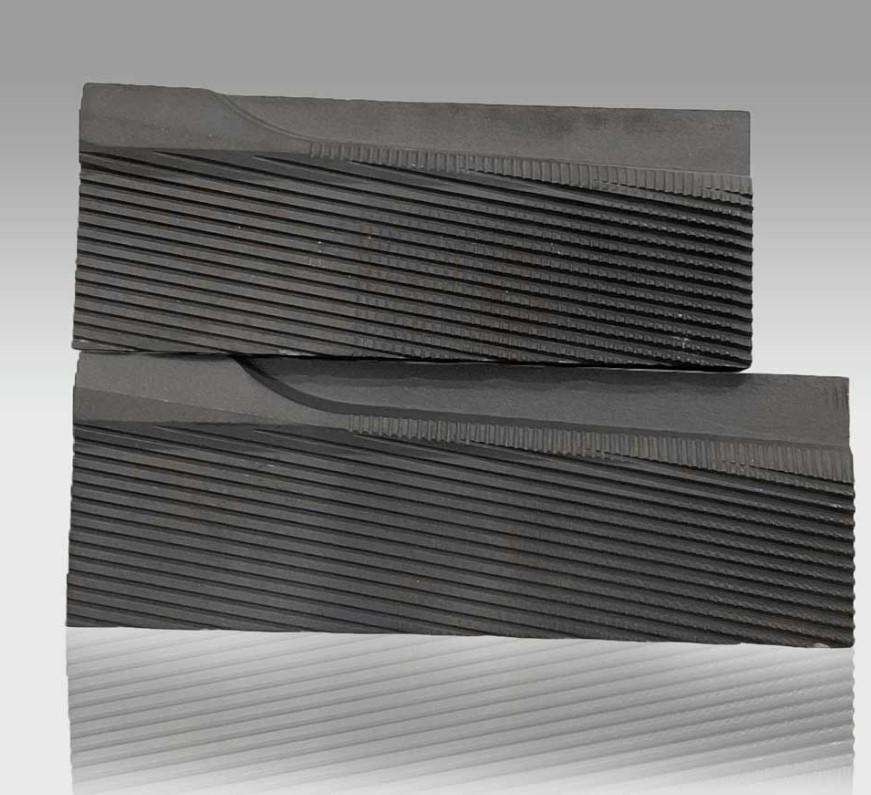

Flat thread rolling dies are specialized tools designed to roll threads on cylindrical workpieces, typically made of metal. These dies feature precise thread profiles that allow for accurate and repeatable thread formation. Before choosing the best flat thread rolling dies manufacturer in India, we should the following points. Here’s why incorporating flat thread rolling dies into your manufacturing process is advantageous:

1. Enhanced Efficiency

Flat thread rolling dies offer unmatched efficiency compared to traditional cutting methods. The rolling process is significantly faster, allowing for higher production rates. Moreover, since thread rolling doesn’t involve the removal of material, there’s minimal waste generated during the process. This translates to higher throughput and lower material costs, ultimately maximizing overall efficiency.

2. Improved Thread Quality

One of the primary advantages of thread rolling is the superior thread quality it produces. Unlike cut threads, which may exhibit variations in thread geometry and surface roughness, rolled threads are more precise and consistent. Flat thread rolling dies create threads with excellent dimensional accuracy, superior surface finish, and enhanced mechanical properties. This ensures that the threaded components meet stringent quality standards, reducing the likelihood of defects and rejections.

3. Extended Tool Life

Flat thread rolling dies are made from high-quality materials, such as tool steel or carbide, ensuring exceptional durability and longevity. Unlike cutting tools that experience wear and require frequent sharpening or replacement, thread rolling dies maintain their integrity over prolonged use. This results in reduced downtime for tool maintenance and replacement, leading to uninterrupted production schedules and lower tooling costs in the long run.

4. Cost Savings

By improving efficiency, enhancing thread quality, and extending tool life, flat thread rolling dies contribute to significant cost savings for manufacturers. The combination of higher production rates, reduced material waste, and lower tooling expenses results in a more cost-effective manufacturing process. Additionally, the superior quality of rolled threads reduces the likelihood of product failures and warranty claims, further minimizing costs associated with rework and customer returns.

5. Versatility

Flat thread rolling dies are highly versatile tools that can accommodate a wide range of thread sizes and pitches. Whether you’re producing fine threads for precision applications or coarse threads for heavy-duty purposes, flat thread rolling dies can be customized to meet your specific requirements. This versatility allows manufacturers to streamline their operations by consolidating multiple thread-forming processes into a single, efficient operation.

Conclusion

In conclusion, flat thread rolling dies are indispensable tools for manufacturers seeking to boost efficiency and reduce costs in threaded component production. From enhanced productivity and improved thread quality to extended tool life and cost savings, the benefits of incorporating flat thread rolling dies into your manufacturing process are undeniable. By investing in these specialized tools, manufacturers can achieve higher throughput, superior quality, and increased profitability, positioning themselves for success in today’s competitive market landscape.