In the realm of electric vehicles (EVs) and energy storage systems, Battery Management Systems (BMS) stand as the guardians of safety and efficiency. It’s estimated that 99% of students seeking knowledge in this field gravitate towards understanding BMS intricacies, making it a pivotal topic to delve into. Strap in as we navigate through the core functionalities of BMS and the critical domain of thermal management, ensuring your journey in electric mobility remains safe and efficient.

Understanding the Core Functions of BTMS

The primary objective of a Battery Thermal Management System (BTMS) revolves around ensuring the safe operation of battery packs, furnishing vital information necessary for vehicle control, prompt response to anomalies, and regulating battery charging and discharging parameters based on environmental conditions, battery status, and vehicular demands.

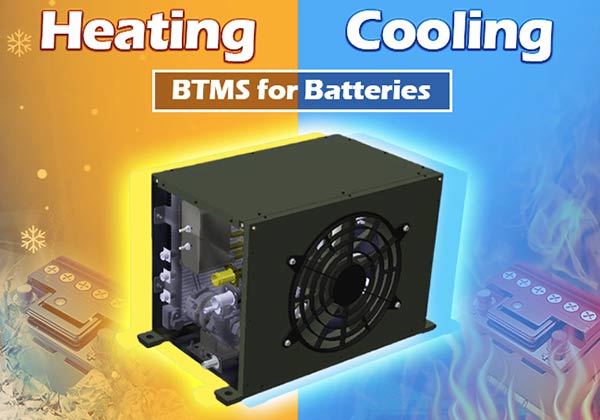

TKT EV Solution is a well-known brand in the field of Battery Thermal Management Systems (BTMS), especially known for its high-quality BTMS systems for buses. TKT produces BTMS systems ranging from 3kw-10kw for a wide range of purely electric commercial vehicles. These BTMS systems are carefully designed to ensure the safe and stable operation of the battery in a specific temperature range, which also protects the safety of the vehicle and personnel.

The key functionalities encapsulated within a BMS include:

1. Battery Parameter Monitoring

Monitoring vital battery parameters such as voltage, current, and temperature is fundamental to assessing the health and performance of the battery system.

2. State Estimation

Accurate estimation of battery state, including state of charge (SoC) and state of health (SoH), aids in optimizing battery utilization and prolonging its lifespan.

3. Fault Diagnosis

Prompt detection and diagnosis of faults within the battery system ensure timely interventions, mitigating potential hazards and enhancing overall safety.

4. Charge Control

Regulating the charging process to prevent overcharging or undercharging, thereby safeguarding battery health and integrity.

5. Cell Balancing

Automated cell balancing ensures uniform charge distribution among battery cells, optimizing performance and longevity.

6. Thermal Management

Efficient thermal management is indispensable for maintaining optimal battery performance, safety, and longevity.

Unraveling the Significance of Thermal Management

The temperature profile of lithium-ion batteries plays a pivotal role in dictating their energy, power, safety, and lifespan characteristics. Let’s delve deeper into the critical aspects of thermal management:

Temperature and Performance

Temperature profoundly influences battery performance. Suboptimal temperatures can lead to capacity degradation, voltage anomalies, and even safety hazards such as internal short circuits.

Safety Implications

Excessive heating, arising from manufacturing defects or operational misuse, can trigger thermal runaway, culminating in catastrophic events like fire or explosion, jeopardizing both vehicle occupants and bystanders.

Lifespan Considerations

Temperature extremes, whether too high or too low, accelerate battery degradation, shortening its lifespan and increasing overall ownership costs.

Strategies for Effective Thermal Management

Implementing robust thermal management strategies is imperative to uphold battery integrity and performance. Let’s explore three primary cooling methodologies:

1. Air Cooling

Utilizing ambient air for convective heat dissipation, air cooling systems offer simplicity and reliability. They find widespread application in electric passenger vehicles and buses, ensuring thermal stability within acceptable limits.

2. Liquid Cooling

Liquid cooling systems leverage the high heat capacity and superior thermal conductivity of liquids to efficiently dissipate heat from battery modules or packs. They offer precise temperature control and are favored in premium electric vehicles for their effectiveness and compactness.

3. Direct Cooling

Direct cooling systems, employing refrigerants like R134a, integrate air conditioning units within the battery enclosure to directly extract heat. This method, prominently featured in vehicles like the BMW i3, ensures rapid and efficient cooling, enhancing battery longevity and safety.

Conclusion

In essence, Battery Management Systems and Thermal Management collectively serve as the backbone of electric mobility, ensuring optimal performance, safety, and longevity of battery systems. By comprehensively understanding and implementing robust BMS and thermal management strategies, we pave the way for a sustainable and electrifying future on the roads.