Introduction

In the realm of construction and industrial projects, the efficiency and precision of drilling play a pivotal role. Traditional drilling methods often fall short when it comes to tackling tough surfaces like concrete or stone. This is where the magic of core drill machines comes into play, revolutionizing the drilling landscape. In this article, we will delve into the secrets behind the power of core drilling, exploring its applications, advantages, and the technology that makes it all possible.

Understanding Core Drill Machines

A core drill machine is a specialized tool designed for making holes in hard materials like concrete, asphalt, or masonry. Unlike conventional drills, core drill machines can penetrate through tough surfaces, leaving a clean and precise hole. The magic lies in their ability to extract a cylindrical core sample, hence the name “core drill.”

The Anatomy of a Core Drill Machine

Before we dive into the secrets of core drilling, let’s understand the key components that make up a core drill machine:

Motor: At the heart of every core drill machine is a powerful motor. This motor provides the necessary torque and speed to drive the drill bit through challenging materials.

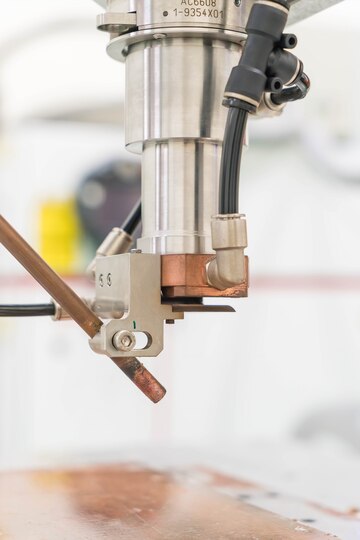

Drill Bit: The drill bit is a crucial element, featuring industrial-grade diamonds or carbide teeth. These materials ensure the durability and effectiveness of the bit when encountering hard surfaces.

Water Supply System: Core drilling generates heat, which can lead to wear and tear on the drill bit. A water supply system is often integrated to cool the bit during operation, increasing its lifespan and maintaining drilling efficiency.

Adjustable Base: Core drills come with an adjustable base, allowing for precise depth control and stability during drilling. This feature is essential for achieving accurate and consistent results.

The Magic Unveiled: Core Drill Technology

Diamonds in Action

One of the secrets behind the power of core drilling lies in the use of diamonds. Diamond-tipped drill bits are exceptionally hard and can cut through even the toughest materials with ease. The industrial-grade diamonds on the drill bit’s surface play a crucial role in ensuring a clean and efficient drilling process.

Wet vs. Dry Drilling

The incorporation of a water supply system in core drill machines adds another layer of magic. While dry drilling is possible, wet drilling is preferred for several reasons. The water serves as a coolant, preventing overheating of the drill bit. Additionally, it helps in controlling dust, enhancing visibility, and improving overall drilling efficiency.

Variable Speed Control

Modern core drill machines often feature variable speed control, allowing operators to adjust the drilling speed based on the material being worked on. This versatility ensures optimal performance and extends the lifespan of the drill bits.

Applications of Core Drill Magic

Construction Industry

In the construction industry, core drilling is a ubiquitous practice. It is employed to create openings for plumbing, electrical wiring, and HVAC systems. The precision offered by core drill machines ensures that these installations fit seamlessly into the structure.

Infrastructure Development

Core drilling plays a vital role in infrastructure development projects. Whether it’s creating holes for bridge anchorages or tunnel construction, core drill machines are indispensable in ensuring the structural integrity of these critical elements.

Exploration and Research

Beyond construction, core drilling finds applications in geological exploration and scientific research. Core samples extracted using specialized drill bits provide valuable insights into the composition of the Earth’s crust, helping researchers understand geological formations and history.

Advantages of Core Drilling

Precision and Accuracy

One of the standout advantages of core drilling is its precision. The cylindrical core samples obtained are clean and accurate, making them an ideal choice for projects where precision is paramount.

Versatility

Core drill machines are versatile tools that can tackle a wide range of materials, from softwoods to the hardest of stones. This versatility makes them invaluable in various industries.

Efficiency and Time Savings

Compared to traditional drilling methods, core drilling is more efficient and time-saving. The power and speed of core drill machines allow for quicker completion of drilling tasks, contributing to overall project efficiency.

Unlocking the Power: Tips for Optimal Core Drilling

Choose the Right Drill Bit: The type of drill bit you choose depends on the material you’re drilling. Diamond-tipped bits are ideal for hard surfaces, while carbide bits are suitable for softer materials.

Proper Water Supply: Ensure a consistent water supply during drilling to keep the drill bit cool. This not only extends the life of the bit but also enhances drilling performance.

Secure the Work Surface: For stability and safety, secure the work surface using clamps or anchors. This prevents the material from shifting during drilling.

Follow Manufacturer’s Guidelines: Each core drill machine comes with specific guidelines and recommendations from the manufacturer. Adhering to these guidelines ensures optimal performance and safety.

Conclusion

In the world of drilling, the magic of core drill machines is transforming the way we approach challenging materials. From construction sites to scientific research endeavors, the precision and power of core drilling are unlocking new possibilities. Understanding the technology behind these machines, their applications, and the tips for optimal usage empowers professionals to harness the full potential of core drill magic. As we continue to advance in technology, the future holds even more exciting developments in the field of drilling, promising greater efficiency and innovation.