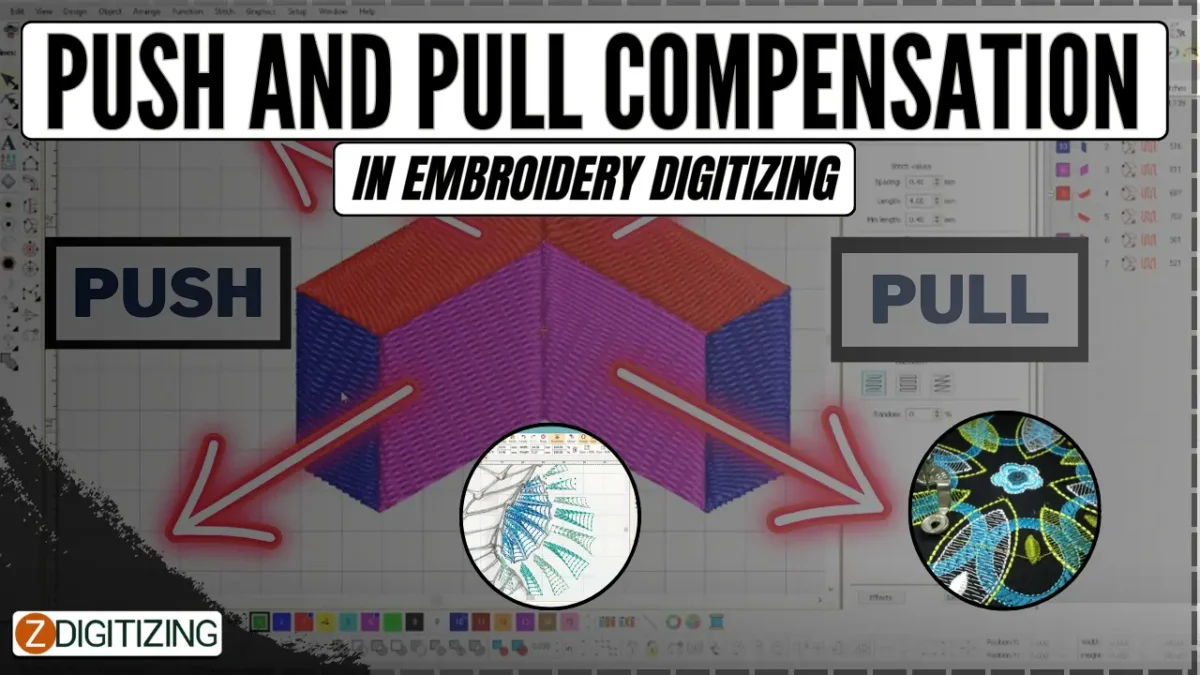

Embroidery digitizing is a complex process that involves translating digital designs into stitch patterns for embroidery machines to follow. One of the key challenges in this process is ensuring that the embroidered design looks as intended on the final fabric. Push and pull compensation are two techniques used in embroidery digitizing to address distortions that may occur during the stitching process. In this comprehensive guide, we will delve into the concepts of push and pull compensation, explore how they work, and discuss their importance in achieving high-quality embroidery results.

Understanding Push and Pull Compensation

Push and pull compensation are techniques used to counteract the forces exerted on the fabric by the embroidery machine’s needle and thread. These forces can cause the fabric to stretch or shrink during the stitching process, resulting in distortions and misalignments in the embroidered design. Push compensation refers to adding extra stitches around the perimeter of an embroidery design to push the fabric back into place, while pull compensation involves adjusting the stitch density or direction to pull the fabric in the desired direction.

How Push Compensation Works

Push compensation is typically applied to areas of the design where the fabric may be pushed or displaced by the needle and thread. For example, when stitching near the edge of a fabric or on stretchy fabrics like knits, the fabric may be pushed outwards by the needle, resulting in gaps or distortions in the design. By adding extra stitches around the perimeter of the design, push compensation helps to stabilize the fabric and prevent it from shifting or stretching during embroidery digitizing.

How Pull Compensation Works

Pull compensation, on the other hand, is used to address areas of the design where the fabric may be pulled or distorted by the stitching process. For example, when stitching long, straight lines or dense areas of stitches, the fabric may be pulled in the direction of the stitches, causing it to shrink or pucker. Pull compensation adjusts the stitch density or direction to counteract these forces and ensure that the fabric remains flat and smooth throughout the embroidery process.

Importance of Push and Pull Compensation

Push and pull compensation are essential techniques in embroidery digitizing for achieving high-quality results and minimizing distortions in the embroidered design. Without proper compensation, the fabric may stretch, shrink, or distort during embroidery, resulting in misaligned stitches, gaps, and uneven texture. By applying push and pull compensation strategically, embroiderers can ensure that the final embroidered design looks as intended and maintains its integrity on the fabric.

Tips for Implementing Push and Pull Compensation

To effectively implement push and pull compensation in embroidery digitizing, consider the following tips:

- Know Your Fabric: Understand the characteristics of the fabric you are working with, including its stretchiness, thickness, and stability. Different fabrics may require different levels of push and pull compensation to achieve optimal results.

- Test Stitch: Always test stitch your designs on scrap fabric before embroidering the final product. This allows you to identify any distortions or issues that may arise during embroidery and make adjustments to the push and pull compensation settings accordingly.

- Use Software Tools: Take advantage of embroidery digitizing software tools and features that allow you to adjust push and pull compensation settings. Many modern digitizing software programs offer built-in tools for automatically applying push and pull compensation based on fabric type and design complexity.

- Customize Settings: Customize push and pull compensation settings based on the specific requirements of each design and fabric. Experiment with different settings to find the optimal balance between stitch density, direction, and placement for achieving the best results.

- Regular Maintenance: Regularly maintain your embroidery machine to ensure smooth and consistent stitching. Clean and lubricate the machine as recommended by the manufacturer to prevent issues such as thread breaks, tension problems, and fabric distortions.

Conclusion

Push and pull compensation are indispensable techniques in embroidery digitizing for achieving high-quality results and minimizing distortions in the embroidered design. By understanding how push and pull compensation work and implementing them strategically in your digitizing process, you can ensure that your embroidered designs look as intended and maintain their integrity on the final fabric. With practice, experimentation, and attention to detail, you can master the art of push and pull compensation and elevate your embroidery to new heights of excellence.

Zdigitizing

We initially established our embroidery digitizing company in 2002, which later expanded to become a worldwide digitizing business. We have a highly-skilled digitizing team capable of handling even the most challenging and complex designs with precision for embroidery digitization.

Our pleasure is to be embroidery digitizers and give embroidery digitizing and vector art services to embroiderers and printers worldwide. Our customers provide us photos of their logos, and we convert them into embroidery formats for use on computerized embroidery machines.

When you interact with zdigitizing services, you can be sure that you’re working with experts who know what they are doing and how to do the project correctly.