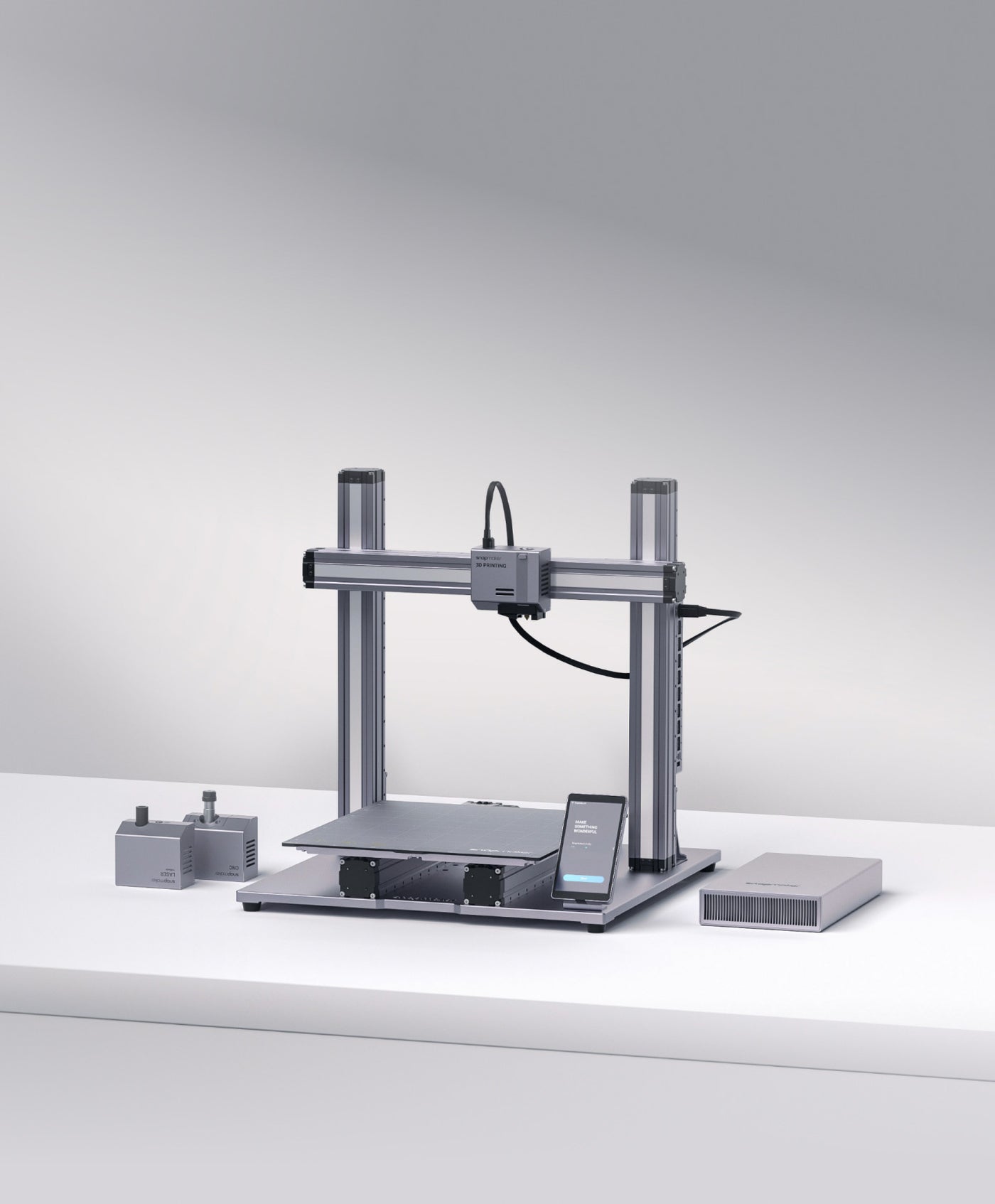

A large 3D printer is a vital tool for companies and people looking to achieve advanced manufacturing capabilities since it provides a host of benefits that cut across any industry. A large-scale 3D printer may be necessary for the following reasons, which are all very convincing:

Scale & Size: A big 3D printer’s capacity to print massive items in a single print is undoubtedly its most notable benefit. Producing life-sized prototypes or components is necessary for testing and validation in industries.

Decreased Assembling Needs: Extensive 3D printing makes it possible to produce elaborate patterns and intricate structures all at once. This can reduce production time and possible sources of failure in the final product by doing away with the need to assemble numerous smaller components.

Tooling and Molds: A variety of manufacturing processes use tooling and moulds made by large-format 3D printers. This is especially helpful in sectors where customised moulds can be made fast and cheaply, like injection moulding.

Applications in Education: Big 3D printers in schools give pupils practical experience in creating and assembling big items. As it prepares them for practical uses, this exposure is beneficial for aspiring engineers, architects, and designers.

In conclusion, the benefits of a large 3D printer are industry-wide, providing enhanced productivity, financial savings, and creative opportunities for individuals looking to push the limits of conventional manufacturing. In the process of producing large-scale products, technology creates new opportunities for innovation, customisation, and efficiency.

The potential of a fast 3D printer to transform manufacturing processes makes them extremely valuable in a wide range of industries and applications. Since speed directly affects production and efficiency, it is an important consideration.