Embroidery, a captivating form of artistic expression, relies on the delicate dance of thread and fabric. Achieving the perfect balance in thread tension is crucial for producing high-quality and visually appealing embroidery. In this comprehensive guide, we’ll unravel the intricacies of thread tension, exploring why it matters, how to achieve the best tension, and troubleshooting common issues that may arise in the pursuit of embroidery perfection.

Understanding Thread Tension

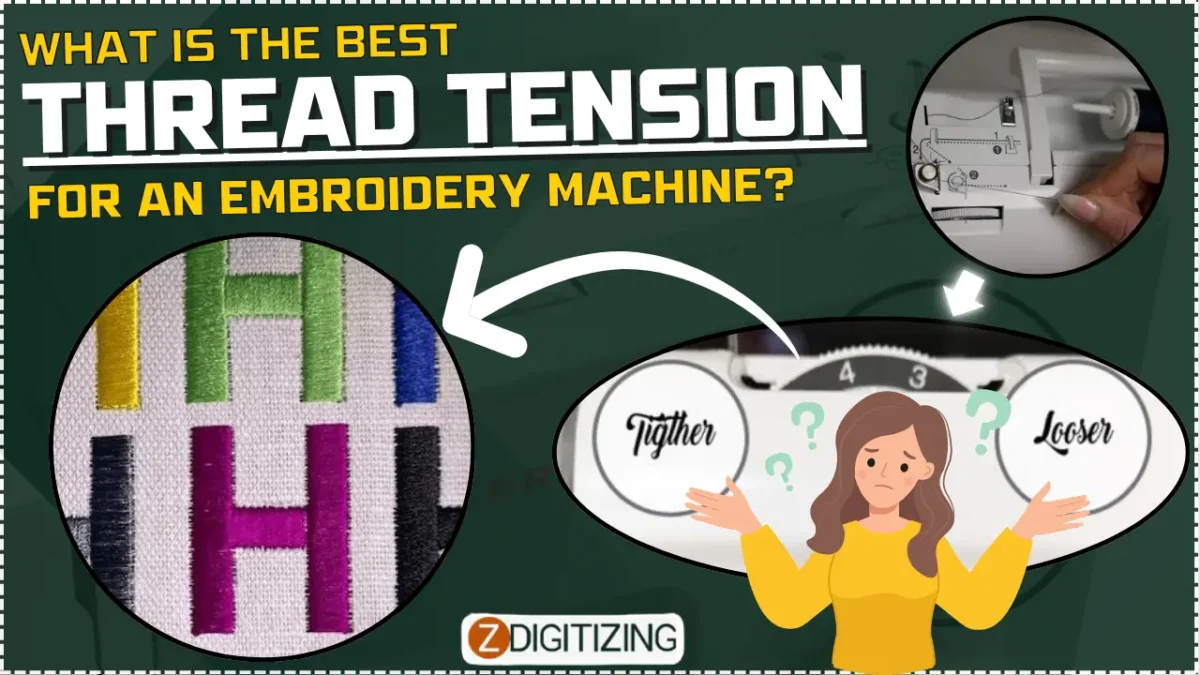

Thread tension refers to the amount of resistance applied to the thread as it passes through the tensioning mechanisms of the embroidery machine. Achieving the ideal tension ensures that the upper and lower threads work together seamlessly, creating clean and precise stitches on the fabric.

Why Thread Tension Matters:

- Stitch Quality: Proper tension contributes to even and well-formed stitches, enhancing the overall quality of the embroidery.

- Preventing Thread Breakage: Balanced tension reduces the likelihood of thread breakage, minimizing interruptions during the embroidery process.

- Fabric Appearance: Correct tension prevents puckering, looping, or distortion of the fabric, maintaining a professional and polished appearance.

- Detail and Clarity: The right tension allows for the accurate placement of stitches, ensuring that intricate details in the design are faithfully reproduced.

Factors Affecting Thread Tension

1. Machine Settings:

- Upper Thread Tension: Typically adjustable through the machine’s tension dial or digital settings.

- Bobbin Thread Tension: Set using the tension screw on the bobbin case.

2. Thread Type and Weight:

- Different thread types (polyester, rayon, metallic) and weights may require adjustments to achieve optimal tension.

3. Fabric Type:

- The thickness and texture of the fabric influence how the thread interacts with the material.

4. Needle Size and Type:

- The needle size and type affect how the thread pierces the fabric. Using the right needle is crucial for proper tension.

5. Stabilizer Usage:

- The choice and application of stabilizers impact how the fabric receives stitches and, consequently, thread tension.

6. Design Complexity:

- Dense or intricate designs may require different tension settings to accommodate the varied stitching demands.

Achieving the Best Thread Tension

1. Start with a Test Stitch:

- Before beginning a project, conduct a test stitch on a sample fabric. This helps in assessing the initial tension settings.

2. Adjust Upper Thread Tension:

- Begin with the upper thread tension. Set it at the midpoint and make small adjustments until achieving the desired balance.

3. Bobbin Thread Tension:

- Adjust the bobbin thread tension if necessary. Some machines allow for easy adjustment through a screw on the bobbin case.

4. Check Needle and Thread Compatibility:

- Ensure that the needle size and type are suitable for the thread and fabric. A mismatch can lead to tension issues.

5. Evaluate Fabric and Stabilizer Combination:

- Consider the fabric type and the stabilizer being used. Experiment with different combinations to find the optimal tension.

6. Test with Design Complexity:

- If your project involves intricate designs, test the tension with a design that reflects the complexity of your intended embroidery.

7. Regular Maintenance:

- Keep the machine well-maintained, including cleaning the tension disks and checking for any lint or debris that may affect tension.

Common Thread Tension Issues and Solutions

1. Thread Too Tight:

- Symptoms:

- Fabric puckering.

- Excessive stress on the thread, leading to breakage.

- Solution:

- Reduce the upper thread tension gradually until achieving a balanced stitch.

2. Thread Too Loose:

- Symptoms:

- Loopy stitches on the upper side.

- Bobbin thread visible on the upper surface.

- Solution:

- Increase the upper thread tension slightly until stitches are balanced.

3. Uneven Stitches:

- Symptoms:

- Stitches appear uneven, with some too tight and others too loose.

- Solution:

- Check for proper threading and tension adjustments. Ensure the bobbin and upper threads are correctly placed.

4. Thread Breakage:

- Symptoms:

- Frequent thread breakage during embroidery digitizing.

- Solution:

- Check for burrs or rough spots on the needle and replace if needed. Adjust tension settings to reduce stress on the thread.

5. Fabric Puckering:

- Symptoms:

- Fabric gathers or puckers around the stitches.

- Solution:

- Reduce upper thread tension, use a suitable needle, and consider using a lighter stabilizer.

6. Bobbin Thread Showing on Top:

- Symptoms:

- Bobbin thread visible on the upper side of the fabric.

- Solution:

- Increase upper thread tension slightly until the bobbin thread is no longer visible.

Conclusion: Perfecting the Art of Thread Tension

Achieving the best thread tension for your embroidery machine is a blend of science and art. It requires a keen understanding of the factors influencing tension, diligent testing, and the ability to troubleshoot common issues. As you embark on your embroidery projects, remember that patience and practice play crucial roles in mastering the delicate balance of thread tension.

Regularly experimenting with different fabrics, threads, and designs allows you to fine-tune your machine settings for various scenarios. Additionally, staying vigilant with machine maintenance and addressing tension issues promptly contribute to a smoother and more enjoyable embroidery experience. With the perfect harmony of thread tension, your embroidered creations will showcase the precision and beauty that define the art of embroidery.

Zdigitizing

We trust this article might really work out for you. To digitize embroiery plan you would require an expert like ZDigitizing, as digitizing is a mind boggling process.

Zdigitizing is a digitizing embroidery service organization that gives embroidery digitizing service and Vector Art Services all around the world to organizations, ventures, and enterprises. zdigitizing gives fashionable, strong, and sensible custom digitizing and vector craftsmanship administrations. We have been conveying first class digitizing embroidery administrations for 20+ years.