When it comes to the manufacturing sector, the sheets play a huge role in it as they form as the base of making a product. Out of the many sheets, the Polycarbonate sheet is indeed one of the best one.

Polycarbonate is a high-performance material in roofing sheets made from plastic resin for windows and lights, wall panels and roof towers, or exterior LED lighting. The polymer’s many beneficial properties make it ideal for various applications, including its low density, excellent resistance to heat and flame, and high levels of electronic clarity and high-intensity resistance.

Important features of Polycarbonate Sheet:

Inexpensive

Cost-effective because of the little overhead associated with transporting and handling these sheets. Consequently, they can be purchased at a lower cost. A square foot of Polycarbonate Sheet can cost very little as compared to the other sheets. These materials’ benefits are that no special coatings or installation tools are needed.

Easy To Install

The commercial sector favors Polycarbonate Sheet because of their low cost and the ease with which they may be installed on-site. A few screws and some rods are needed to get them back in place, so you won’t need any complicated machinery or cranes to get the job done. Welding these sheets requires little to no work, and you may cut them with sharp scissors or a circular saw.

Ultraviolet Protection

The transparent polycarbonate sheets’ UV protection and impact resistance make them ideal for outdoor use. They retain their excellent surface and transparency even at temperatures as high as 120 degrees Celsius. It’s the best option if you want lots of natural light to flood without worrying about UV damage. Greenhouses typically have polycarbonate roofs like those used in this type of structure. The plants benefit from having enough light and nutrients to flourish.

Fire Resistance

Polycarbonate Sheet, like metal roofing sheets, offer excellent fire protection. Intense heat, noxious gases, and flaming debris are contained within these sheets. It doesn’t swell up and puts extra pressure on structures, even when the temperature rises. Places prone to fire can benefit from polycarbonate sheets.

Low-Maintenance

In contrast to glass ones, FRP Roofing Sheet requires almost any upkeep. Corrugated polycarbonate sheets are a low-maintenance option for your home or business since they repel water and other residues. Sheets like these are frequently installed in garages, skylights, greenhouses, and pergolas.

Insulation

As a result of the insulation, the interior of the building is safeguarded from the elements. Multiwall polycarbonate, if properly installed, can be pretty insulating against various climates. In the winter, it keeps you toasty, and in the summer, you may relax in the refreshingly cool air. It finds use in residential and commercial construction, interior decoration, and agricultural structures.

What are the varieties of Polycarbonate Sheets?

Clear Polycarbonate

Skylights, sign faces, covered walkways, and other applications requiring transparency have seen a dramatic increase in the use of polycarbonate in recent years. For a good reason, too, as polycarbonate is 250 times more impact resistant than glass and has higher tensile and thermal resistance to boot. These polycarbonate sheets won’t yellow, haze, shatter, or otherwise diminish their transparency. This is the best option if you need something that will stay clear and last forever, even in the most challenging conditions.

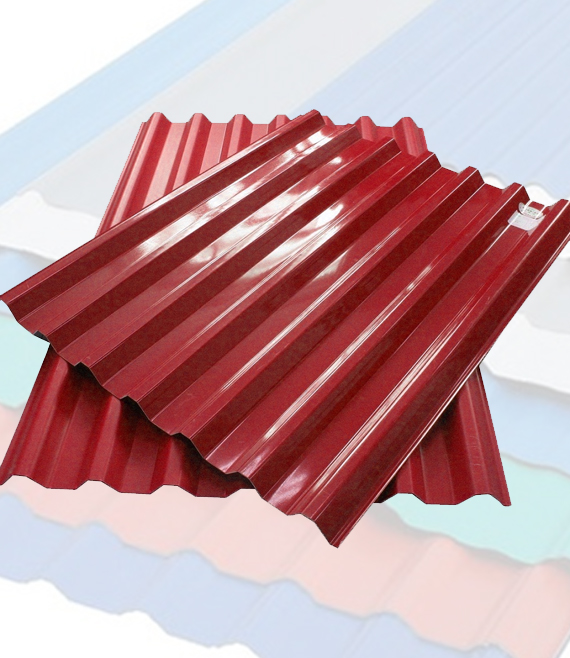

Colored or Tinted Polycarbonate

Polycarbonate Sheet need not sacrifice aesthetics for strength. Check out our selection of colored polycarbonate sheeting if you’re interested in using polycarbonate sheeting as the focal point of an eye-catching display or advertisement. With these vivid colors and the versatility of polycarbonate for on-site cutting and forming, your creativity is the only limit to what may be created.

Mirrored Polycarbonate

Everyone appreciates glass’s aesthetic value, but nobody likes how quickly it may be damaged. Because of this, mirrored polycarbonate exported by Polycarbonate Sheet Exporters in India has taken over as the material of choice for mirrors that a curious glance can’t break. Polycarbonate mirrors have been implemented in various industries, including the automotive, dental, cosmetic, and penal sectors. Because they are as clear as glass but far more durable, polycarbonate mirrors can withstand extreme conditions.

Bulletproof Polycarbonate

This thick sheet of polycarbonate is the stuff that gets called bulletproof “glass” and is employed extensively in the financial, law enforcement, security, and incarceration sectors. In the unlikely event that you’ll need the material to live up to its moniker, the seven-year warranty that Polycarbonate Sheet Manufacturers in India offer on its bulletproof polycarbonate should put your mind at ease.

Abrasion-Resistant (AR) Polycarbonate

Polycarbonate sheets are more easily scratched than glass or other polymers, which is one of its disadvantages. Polycarbonate Sheet Suppliers in India recognized the need for a more robust and flexible material and developed a line of polycarbonate sheets to fill it. This material is perfect for institutional settings where wear and tear from repeated use is a significant concern, such as schools, hospitals, and prisons. The cost of this polycarbonate may be higher than that of some of our other options but think of the money you’ll save in the long run thanks to its scratch resistance.

Conclusion

Polycarbonate Sheet has risen in popularity due to their remarkable eco-friendliness. They are steel sheets with translucent sheets added to maximize the amount of natural light allowed into the manufacturing facility. Due to their superior quality and thickness, these sheets have largely supplanted glass and acrylic.

FAQs

- What are the drawbacks of polycarbonate sheets?

Polycarbonate’s biggest drawback is that it scratches easily. Hence, it is very essential to be a little delicate with it.

- How fragile is a polycarbonate sheet?

Polycarbonate also has the quality of being exceedingly malleable. Like aluminum sheet metal, it may be produced at room temperature without splitting or breaking.

- How durable are polycarbonate sheets?

The tensile strength of polycarbonate is generally between 55 and 75 MPa (force per unit area). Although polycarbonate can be up to 200 times more potent than glass in tensile strength, acrylic, another plastic option, is around 4-8 times stronger.