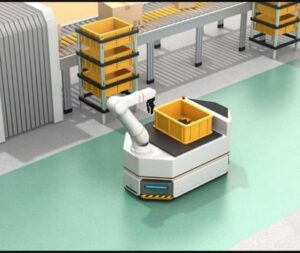

Automated material handling systems, or AMHS, ensure that materials are transported efficiently from one location in the manufacturing area to another – whether inside the same department or bay, on opposite ends of the manufacturing floor, or even in two different buildings.It moves material utilising conveners, vertical elevators, and autonomous vehicles, using route and process step information from the MES.To detect the location of a substance, several technologies such as OCR RFID, barcoding, near-field communication, and ultra-wide band indoor tracking are used to identify it.

An Automatic Material Handling System tries to tackle these issues and offers the following advantages:

Improved cycle times –

The material does not have to wait for the operator to carry it. The AMHS is in charge of this, allowing operators to focus on responsibilities in their allocated region. The time it takes to transit from one step to the next becomes more predictable, allowing for more accurate cycle time estimations and customer due date estimates.

Contamination is reduced-

Some production environments are vulnerable to airborne particles that are easily stirred up by people’s activity and, as a result, contaminate the product being manufactured. Particulate-sensitive surroundings can benefit from efforts to prevent needless movement.

Material placement is made easier –

Implementing carrier and material tracking systems is part of a truly automated material handling system. The AMHSs can be used to locate material that is missing owing to damaged or disabled identifiers because they are always tracking the whereabouts of a certain part, carrier, or item. This is especially beneficial in high-volume production.

Observance of regulatory requirements –

Companies must comply with restrictions in nations such as the United States, which set a maximum weight that an employee can lift without help.

Apod of 25 300 mm wafers weights roughly 16.5 pounds (4.5 kg) in semiconductor fabrication.

The heavy lifting can be delegated to AMHSs.

Additionally, AMHSs do not require breaks, do not request vacations, do not become ill, and are less likely to mishandle a heavy pod of pricey material.