All units of the car are connected to each other. Due to this, the vehicle is a single mechanism in which every spare part counts. Let’s take a closer look at a small detail that no car can do without. This is the auto oil seal. What is it, what are its characteristics, when does it need to be replaced, and how can this be done using the example of a crankshaft auto oil seal?

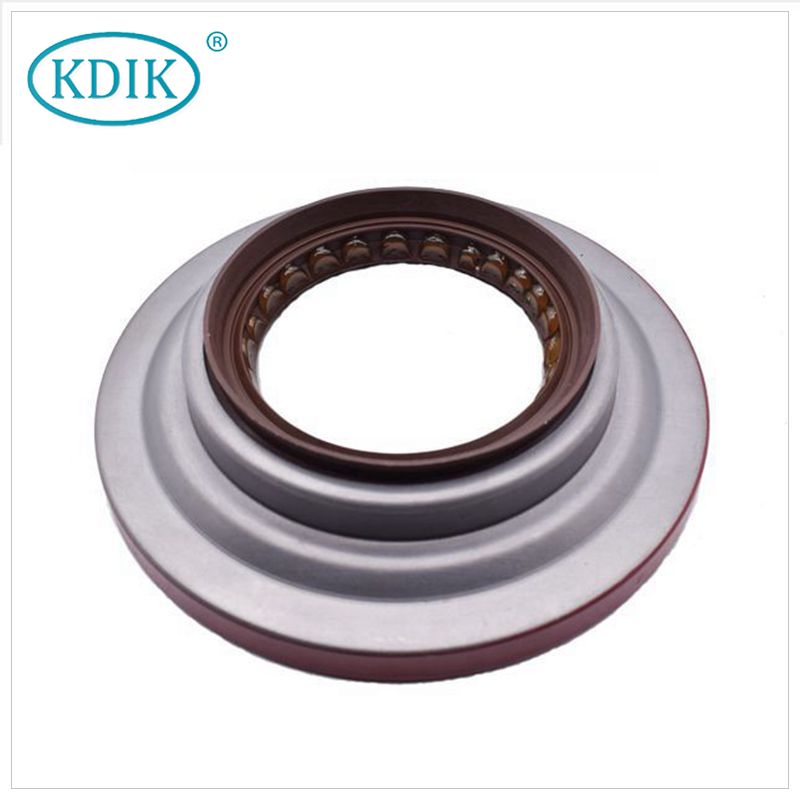

The auto oil seal is a sealing element installed at the connection between various mechanisms and the rotating shaft. In addition, similar parts are mounted on the parts that perform the reciprocating motion to prevent oil leakage between the movable element and the body of the mechanism. Regardless of design and purpose, the device is in the form of a ring with a compression spring. Parts can be of different sizes and made of different materials.

The auto oil seal is enclosed in a housing through which the mechanism spindle passes. There is a sealing material inside the housing. It is on all sides of the shaft that will come out of the unit body, such as a motor or gearbox. The diameter of the product should be such that, during pressing, its seal is pressed tightly against the spindle from the inside, and from the outside – on the fixed part of the mechanism.

In addition to their sealing function of preventing grease leakage, the auto oil seal also acts as a dust seal, trapping dirt and preventing it from entering the mechanism.

In order for a part to remain effective under different operating conditions, it must meet the following properties:

Due to the vibrations that occur during the operation of the unit, the seals must be resilient, which will reduce wear on the components themselves and working parts. The stuffing box must prevent grease from flowing out of the equipment and therefore come into contact with chemically active substances. Therefore, the material should not deteriorate due to contact with grease. Constant contact with moving and rotating parts can cause the seal contact surfaces to become very hot. For this reason, it is important that the material of this element retains its properties, whether in the cold (for example, when the car is parked in a parking lot in winter) or when driving for long periods of time in the hot summer.

The number and design of auto oil seals depends on the car model and its function. In any vehicle with an internal combustion engine, there are definitely two seals present. They are mounted on both sides of the crankshaft.

In addition to this part, the following auto parts need to be sealed:

Valve stem (also called valve stem or valve cover) of the valve train;

timing camshaft;

oil pump;

front wheel drive vehicle hubs;

bogie;

Rear axle reducer;

differential;

rear axle;

Gearbox.

What material is the auto oil seal made of

Since the contact surfaces of the product and mechanism can be very hot, the gland must be heat resistant. In addition, the increase in heating temperature is due to the constant friction of the edges of the parts during the rotation of the shaft. If the manufacturer uses normal rubber or other materials that are not resistant to high temperatures to make this element, accelerated destruction of the stuffing box is guaranteed.

Crankshaft and camshaft seals should have such properties because these components are constantly thermally loaded and subject to friction when the engine is running.

The same goes for the hub seals. They must use high-quality materials. In addition to being resistant to friction and high loads, these parts must have a high-quality durable body, and major parts must be reinforced. The edge should have an extra elastic element to keep dirt from getting into the knot. Otherwise, the working life of the stuffing box will be significantly reduced, and the mechanism itself will not be able to serve for a long time.

Manufacturers of these parts can use the following materials:

NBR – Rubber made of butadiene rubber. The material retains its properties over a wide temperature range: from minus 40 degrees to +120 degrees. auto oil seals made of this rubber are resistant to most lubricants and do not deteriorate when fuel touches their surfaces.

ACM – Rubber with acrylate structure. The material falls into the cheap commodity category, but has good properties suitable for making such products. Automotive acrylic rubber auto oil seals can work in the following temperature range: -50 to +150 degrees. Hub seals are made of this material.

VMQ, VWQ, etc. – Silicone. This material is often problematic – due to contact with certain types of mineral oils, the destruction of the material may be accelerated.

FPM (Fluoroelastomer) or FKM (Fluoroplastic) – the most common materials today. Its effect on chemically active fluids used in automobiles is neutral. This seal can well withstand thermal loads in the range of -40 to +180 degrees. In addition, the material has good resistance to mechanical stress. Mostly it is used to make seals for power plant components.

Teflon – Teflon. Today, this material is considered ideal for making seals for vehicle components. It has the lowest coefficient of friction and an allowable temperature range from -40 to +220 degrees Celsius. No technical fluids used in the machine will damage the auto oil seals. It is true that such parts cost considerably more than other analogs, and during installation, the manufacturer’s replacement recommendations must be followed exactly. For example, the contact surface between the shaft and the mounting site needs to be wiped dry before installing the seal. The part comes with a mounting ring that can be removed after pressing down.

How to choose an auto oil seal for a car

The advantage of most auto oil seal modifications is low cost. True, when the master does the work of replacing the seals, the price of such a procedure is several times more expensive than the price of the part itself.

In addition to the price of the element, there are many factors that influence the choice:

Which node the product will be used for. The most loaded glands must withstand continuous heating above 100 degrees, have a minimal coefficient of friction, and be resistant to chemically active technical fluids.

This section must be specific to the environment. For example, if an old product is used to contain antifreeze, a new seal must be created to contact such substances.

Do not use analogs designed to be installed on other devices. It’s best to buy auto oil seals for the institution of a specific car brand. If you can’t find the original, then you can buy an analogue from another manufacturer. This eliminates failures due to improperly installed seals.

brand. Some motorists mistakenly believe that the word “original” always means that the part was made by the automaker itself. But usually this is not the case. The truth is that most auto businesses either have a narrow, separate segment under them, or use the services of a third-party company but put their own labels on the ordered batches. On the auto aftermarket, you can find parts that are as good as the original, and in some cases even better. On the other hand, some people wonder if it’s really worth paying for a brand given the opportunity to buy a cheaper equivalent. In short, there is a reason for this purchase, because self-respecting companies try to maximize product quality, which leads to higher product prices.

In addition to these factors, drivers should pay attention to the following nuances when purchasing new auto oil seals:

If buying a knockoff rather than the original, it is important to make sure its design exactly matches the old part;

The width of the new gland may be smaller than the width of the old element, but not wider, as this would complicate or make installation of the new gasket impossible. The diameter of the contact hole through which the shaft passes should match the size of the main shaft;

Are there boots on the new parts – the threads that keep dust and dirt out of the mechanism. In most cases, this part consists of two elements. The first is the boot itself, the second is the wiper;

If you buy non-original parts, you should give priority to well-known brands and don’t obsess about the cheapest products;

On domestic cars, you can use analogues designed for foreign cars. The contrary is unacceptable, despite the recent marked improvement in the quality of some parts of domestic production;

A notch can be made inside the gland. In the direction of this element, all parts are divided into three categories: left-handed, right-handed and universal (can remove oil, regardless of the direction of rotation of the shaft).

When selecting new parts, pay attention to their dimensions. To speed up your search and eliminate the possibility of buying an unsuitable auto oil seal, you need to pay attention to its markings. Most manufacturers put the following designations on the valve body: h – height or thickness, D – outside diameter, d – inside diameter.

How to Replace the Crankshaft auto oil seal

Before choosing a new auto oil seal, the first thing you should be aware of is the possible wear at the contact points of the old parts. This wear should be taken into account when choosing a simulation. If the diameter of the seal does not match the size of the shaft, the part will not be able to do its job and the technical fluid will still leak.

If you can’t buy a repair sim in the product (which is very rare, except you can search in the options for other cars), you can buy a new auto oil seal and just install it where the edges don’t fall in and you can wear it. When the bearing in the mechanism is worn but still cannot be replaced, the new auto oil seal on the inside should have a special oil-containing groove.