A fused deposition modeling 3D printer can have one or two nozzles, known as dual extruder 3D printers. Even so, the most popular printers are the ones with one extruder. Still, the one with two extruders allows the user to use multiple filaments at the same time, different colors, and still produce a very high-quality 3D object.

When a printer has two nozzles or extruders, it is called a dual extruder 3D printer. At the same time, there are two kinds of dual extruders. They include;

- Dependent dual extruders are stuck together and move in the same direction with another nozzle.

- An Independent dual extruder allows the nozzle to move separately from each other. Each head has its nozzle and can comfortably print with the same or different material than the other. This flexibility has made it the best-selling machining tool since its introduction. Apart from that, there are other reasons people craze them. They include:

- You will realize that with a dependent dual extruder, the nozzle has been placed close together, that if one of the nozzles is inactive, the problem of oozing will be noticed. But this is quite different with the independent dual extruder, which allows one inactive nozzle to stand in idle mode at the side of the bed while one is printing.

Additionally, independent extruders support each head having its own nozzle and filament. So, when one nozzle is active, the other won’t ooze on the printing area and contaminate the model being created, but it will move to the sides of the bed. Also, some IDEX 3D printers come with a whipping system that cleans the nozzles, minimizing the possibility of mixing and contaminating colors when switching from one color to another.

- IDEX dual extruder printer enables two nozzles to have two significantly different temperatures, thus allowing the combination of different materials. And since the heads are independent of each other, it is possible to set the nozzles at different temperatures with a significant temperature difference between them. Therefore, allowing the user to make many more material combinations. For example, you can use a more complex detailed print using soluble support.

- The two identical parts printing is made possible by an independent dual extruder 3D printer. Thus, doubling the production rate of the printer makes it more effective for serial manufacturing.

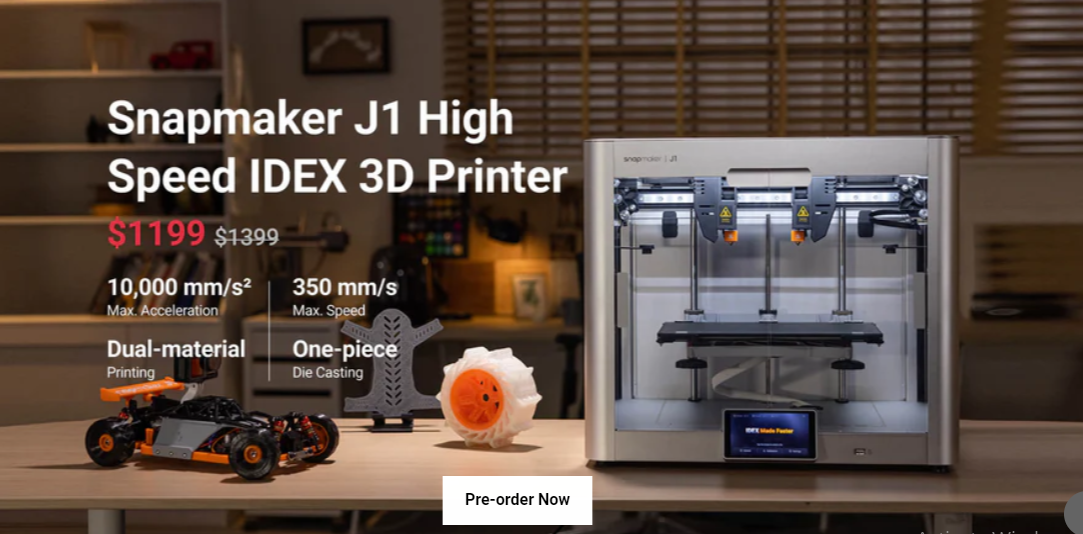

Combining these benefits, Snapmaker has produced a more advanced 3D printer like no other. The printer is known as Snapmaker J1 3D – the best dual extruder IDEX 3D printer. Why is the best dual 3D printer ever? Here are the reasons;

Its extruders are redesigned to deliver a superb performance consistently with demanding advanced material. It enables the user to easily print high-quality projects that meet the functional and structural demands of various engineering applications.

It has been made with a backup mode. How does this mode work? You can print with one nozzle while the other stands by. If the working nozzle bumps into a hiccup, the standby extruder will take over the job coherently and still deliver a fabulous print to you. So, it enables you always to have a plan B for ace performance.

The Snapmaker IDEX J1 3D printer is the only powerful extrusion system with two separate extruders moving independently on the X-axis, allowing you to run two separate prints simultaneously. Therefore, the ultimate benefit that this aspect will deliver for you is halving your wait time while doubling your productivity.

The machine enables you to choose different settings for two nozzles to maximize the performance of individual filaments.